UV aging test chambers are crucial equipment for testing the weather – resistance performance of items under ultraviolet light conditions and are widely applied in numerous industries. However, customers are prone to falling into certain pitfalls when selecting such test chambers. Here, the editor will outline key selection points to help you avoid these “traps”.

Price Traps: Don’t Be Blinded by Low Prices

When purchasing UV aging test chambers, price is often the first factor that customers pay attention to. Nowadays, the market for test chambers is highly competitive, with price wars among manufacturers breaking out one after another. Many customers are solely focused on saving on the initial equipment purchase cost, overlooking subsequent operating and maintenance expenses. In fact, the starting price of a device does not fully represent its long – term usage cost. A seemingly low – priced test chamber may have high energy consumption and frequent malfunctions during operation, leading to a significant increase in repair and energy costs. Therefore, when considering the price, customers should conduct a comprehensive and all – around evaluation. They should not only focus on the expenditure at the time of purchase but also take into account the overall cost of the equipment throughout its entire lifecycle.

Quality Inspection: A Field Visit Reveals the Truth

The quality of a test chamber directly affects the accuracy and reliability of the test results. To ensure that the purchased equipment is of high quality, an on – site inspection is an indispensable step. Customers should personally visit the manufacturing enterprise to gain an in – depth understanding of its production processes, quality control systems, and the actual operation of the equipment. Through an on – site visit, customers can have a direct perception of the enterprise’s production capacity and management level, and make a more accurate judgment on the quality of the test chambers. Avoid placing orders blindly based solely on online promotions or sales staff’s verbal descriptions, so as not to buy a product of poor quality that will affect subsequent testing work.

Performance Key Points: Precision, Efficiency, and Low Energy Consumption

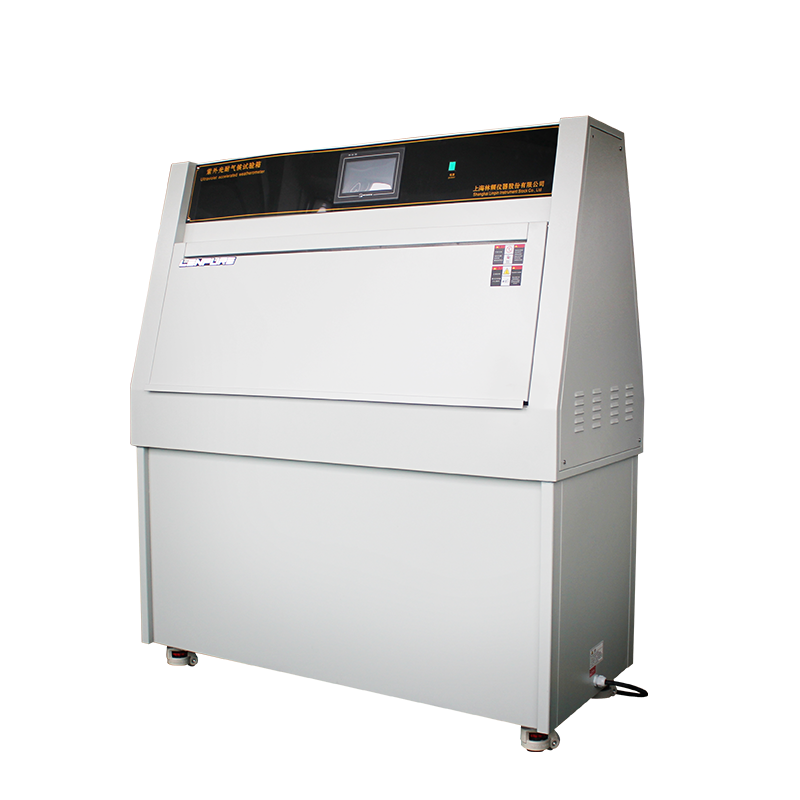

The accuracy, efficiency, and energy consumption of a test chamber are important indicators for measuring its performance. A well – performing test chamber should not only meet customers’ basic requirements for material testing but also excel in terms of test accuracy and operating costs. A high – efficiency test chamber can shorten the testing cycle and improve work efficiency. High – accuracy test results can provide a reliable basis for product research and development and quality control. Low energy consumption helps reduce long – term usage costs. Therefore, it is recommended that customers choose test chamber products that incorporate new technologies. For example, the test chambers produced by Linpin Instruments have won the favor of many customers with their remarkable advantages of high precision, high efficiency, and good quality.

UV aging test chambers have a wide range of applications in numerous industries such as solar energy, automobiles, auto parts, power, new materials, coatings, rubber and plastics, chemicals, optics, electroplating, cables, and printing. When making a purchase, customers must keep a clear head, avoid blindly pursuing low prices, and instead comprehensively consider multiple factors such as price, quality, and performance. They should select a UV aging test chamber that is reliable in quality, reasonable in price, and superior in performance. It is hoped that through the above suggestions, more customers can choose satisfactory test equipment to provide strong support for their enterprise’s research and development and production.