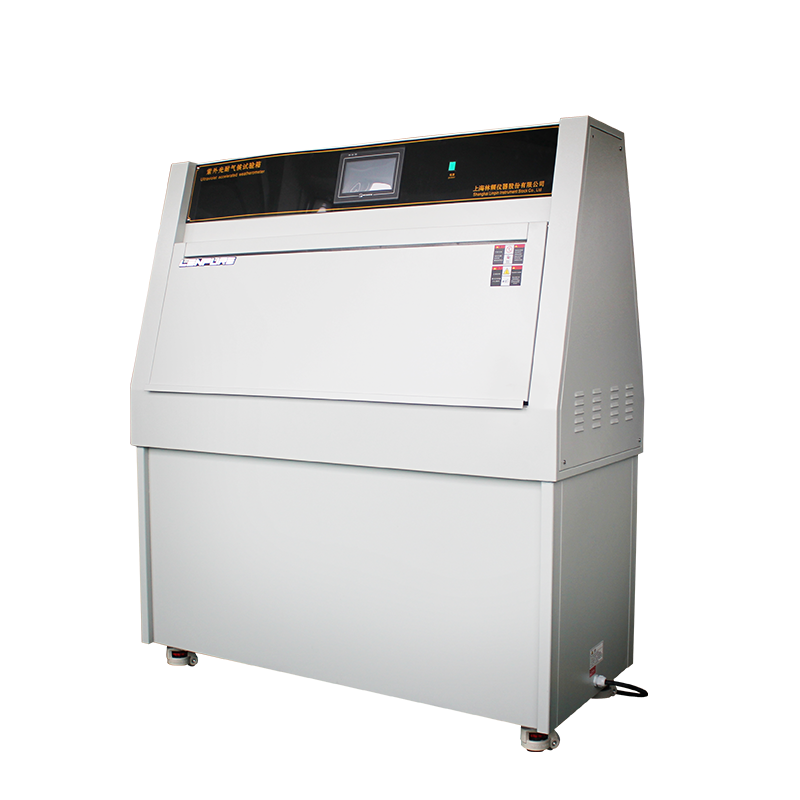

An aging test chamber does not refer to a single device but encompasses various testing methods, including xenon lamp aging tests, UV aging tests, high-temperature aging tests, air-exchange aging tests, and salt spray corrosion aging tests. These chambers play a crucial role in simulating artificial environmental climates.

These chambers primarily test products and materials such as cables, wires, and insulators, examining changes before and after aging to assess properties like tensile strength and elongation rate.

However, like any equipment, proper maintenance is essential to ensure optimal performance during testing and smooth operation. So, how can we better maintain an aging test chamber? Below are some key points:

Do Not Use the Chamber as an Oven – Avoid using it to dry food, clothing, or other unrelated items.

Regularly Check for Electrical Safety – To prevent electrical leakage, periodically inspect the grounding system.

Monitor Motor and Fan Noise – If abnormal sounds occur in components like the motor or blower, inspect them promptly, identify the cause, and perform regular cleaning and lubrication.

Inspect Before Long-Term Reuse – If the chamber has been unused for an extended period, conduct a thorough inspection before restarting to prevent hazards such as loose wires or short circuits that could lead to fires.

Handle Smoke or Fire Safely – If smoke or fire is detected, do not immediately open the chamber door. First, assess the situation to ensure safety. When opening the door, stand to the left side to avoid injury from high-pressure gas release.

Clean and Power Down After Use – After each use, turn off the main power, wipe away moisture, and keep the chamber clean and dry to prevent corrosion.

To maximize the aging test chamber’s value, extend its lifespan, and ensure reliable testing performance, proper maintenance is essential. Only with diligent care can the chamber consistently deliver its best performance during experiments.