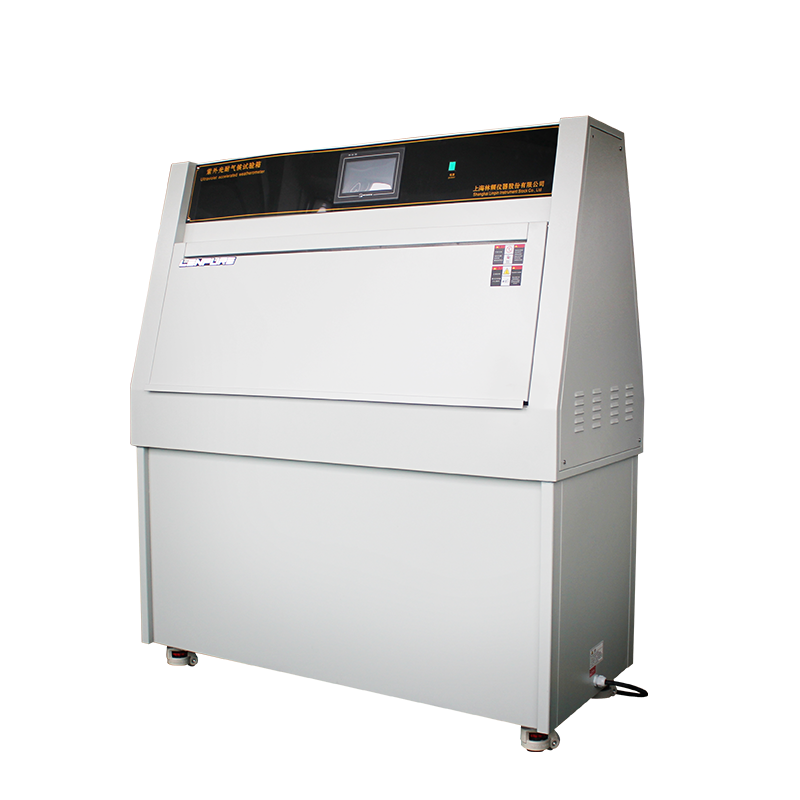

UV aging test chambers are designed to simulate three environmental conditions to evaluate the performance parameters of objects under ultraviolet (UV) radiation and other factors. During testing, the equipment can replicate multiple natural environments. Today, we will focus on the three simulated conditions: condensation, UV radiation, and rain.

Condensation Environment: Many items are exposed to prolonged outdoor humid conditions, often caused not by rain but by dew. The UV aging test chamber simulates outdoor moisture erosion through its condensation function. During the condensation cycle, water in the bottom reservoir is heated to produce steam, which fills the test chamber. The steam maintains 100% relative humidity and a high temperature inside. Since the test samples are fixed to the sidewalls of the chamber, their exposed surfaces interact with the humid air inside, while the unexposed side remains cooler. This temperature difference causes continuous condensation on the test surface, forming liquid water throughout the cycle.

UV Radiation: This is the core function of the test chamber, primarily assessing the material’s resistance to UV exposure. UV radiation is simulated using UV lamps. Different lamps emit varying wavelengths and intensities of UV radiation, so users must select the appropriate lamp based on the material’s testing requirements to achieve the desired UV exposure levels.

Rain Simulation (Water Spray): In real-world scenarios, sudden rainfall can rapidly dissipate heat accumulated under sunlight, causing a sharp temperature drop in materials. This thermal shock, along with rainwater erosion, can affect material durability. The water spray function in the UV aging test chamber effectively simulates such thermal shocks and corrosion, allowing for the evaluation of a material’s weather resistance under these conditions.