Stability is crucial for the accuracy of test results in aging test chambers. Are there any methods to maintain and improve the stability of the chambers during use? Depending on their purpose, aging test chambers can be categorized into various types, such as salt spray corrosion aging, ozone aging, high-temperature aging, UV aging, air-exchange thermal aging, and xenon lamp aging tests. Different types of test chamber equipment can enhance their stability in certain aspects.

The choice of raw materials has a certain impact on the stability of aging test chambers. High-quality materials have a longer service life and can better maintain the stability of the equipment. Therefore, it is important to pay attention to the materials used when purchasing the equipment.

The design and technology employed in the test chamber equipment directly affect its stability. Different manufacturers use varying technologies, and some applications can improve the stability of the test results. Thus, selecting equipment that incorporates advanced technologies is essential.

Ensuring correct operation during the use of the test chamber equipment, as well as proper parameter settings, also influences the stability of the chamber. The equipment should be operated according to the instructions in the product manual to avoid malfunctions caused by improper operation, which could compromise stability and reduce the accuracy of test results.

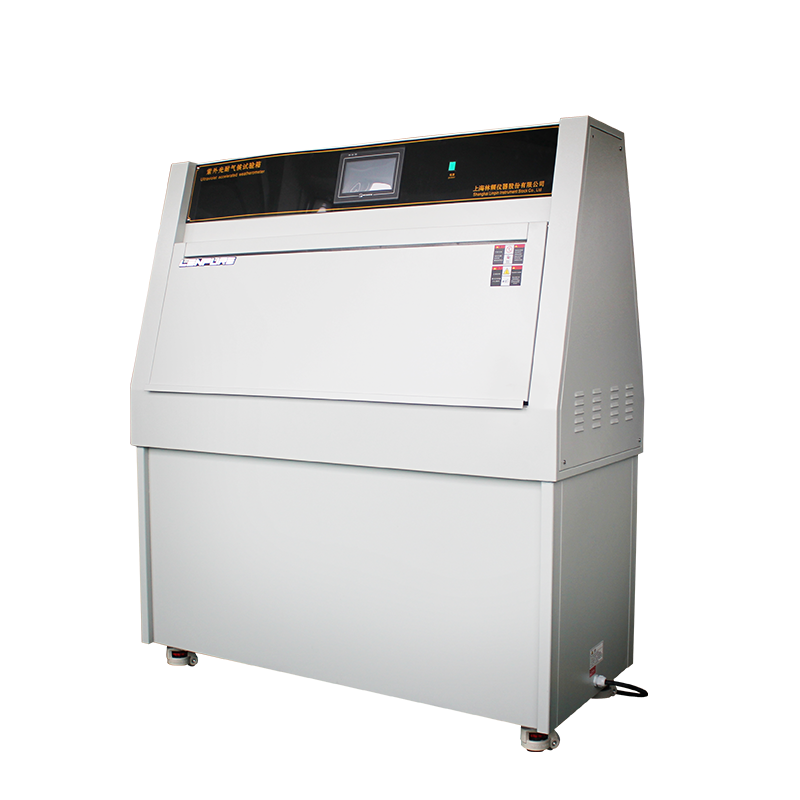

The stability of aging test chamber equipment can be enhanced through the above points. Customers can also use these criteria to select suitable equipment. Our company’s aging test chambers are made of high-quality raw materials, utilize cutting-edge technologies, and provide standardized technical guidance services, ensuring higher stability and more accurate test results. This is why many customers choose our test chamber equipment. After purchase, we also offer comprehensive after-sales services to promptly address technical and other issues for our clients. Currently, we have established long-term partnerships with tens of thousands of customers. We welcome more customers with needs to visit our factory for selection or call 400-066-2888 for more detailed equipment specifications.