Now that winter has arrived and snow has begun to fall in some areas, how can companies properly maintain their UV aging test chambers while in use?

As the saying goes, “In dry weather, be cautious of fire.” Winter is characterized by dry air, so it is essential to take fire prevention measures when using a UV aging test chamber. Ensure that there are no flammable items around the equipment. Since snowfall can be frequent in winter, check whether rainwater has entered the room around the equipment after it snows. If snow or rainwater lands on the equipment, it should be wiped off promptly to avoid rust caused by prolonged water stains. If rust does occur, immediate rust removal and anti-rust measures should be taken. Additionally, low temperatures in winter can cause some components to become hard or brittle. Therefore, during equipment use, be cautious to prevent equipment damage that could interrupt the test. Prolonged operation of the equipment at low temperatures may also affect the test results. Technicians need to pay attention to controlling the temperature and humidity around the equipment to ensure that the installation environment is within the appropriate temperature and humidity range. These are the key points to focus on in winter. Cleaning of other components can be carried out on a fixed schedule.

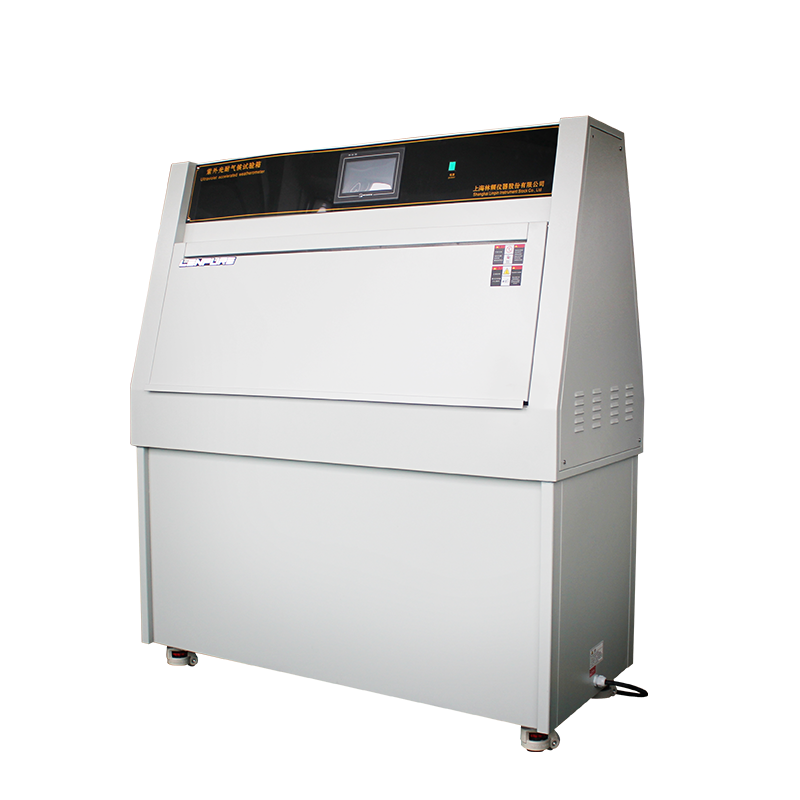

The maintenance of a UV aging test chamber is not a one-time task but requires long-term commitment from the staff. As seasons change, maintenance measures should also be appropriately adjusted. Proper maintenance can extend the service life of the test equipment. Of course, extending the equipment’s service life also requires strong technical support. Technicians can promptly identify and resolve faults to prevent more severe losses for customers. Our UV aging test chambers are made from high-quality raw materials and meet customer needs in terms of material and craftsmanship. We also provide long-term technical support. We have established offices in multiple regions to handle technical issues for customers in a timely manner, ensuring they enjoy one-stop service.