Climate Chambers ISO 4892-1 UV-Lamp Weathering Test Chamber

Lenpure UV-Lamp Weathering Test Chamber Take fluorescent UV lamp as light source to simulate the UV irradiation in natural light and condensation to conduct accelerated weathering test to the materials. It can simulate the UV, rain, high temperature, high humidity, condensate, darkness and other environmental conditions in natural climate and combine them in a circle, and carry out these circles automatically.

Feature

▪Black Panel Temperature (BPT) Control

▪Touch-screen controller, user-friendly

▪With irradiance monitor function

▪Import Q-Lab air-cooled UV lamp, more economical, more efficient and easier to maintain. Lamp life of 1800 hours.

▪Door Safety and Over-temperature Shutoff

▪The irradiance control system continuously monitors and controls the output of the light, which ensures accurate exposure and repeatable test results.

▪Allows the user to simultaneously control and monitor relative humidity, blackboard temperature and air temperature in the box.

▪All circuits fused or circuit breaker protected, overload protection.

▪CE Compliance and UL & CSA Certified

▪ Tri-color Indicator and EMO (Emergency-off Switch) available.

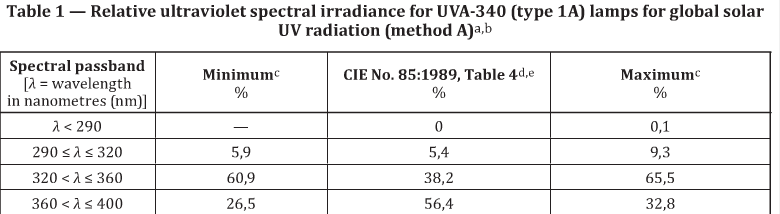

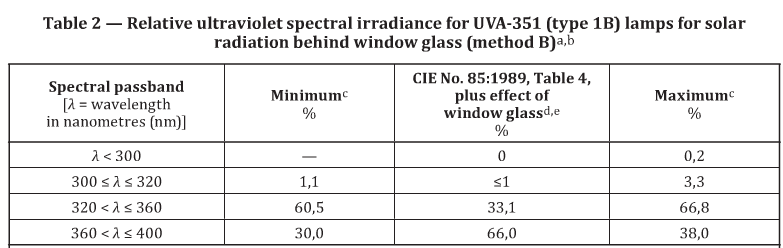

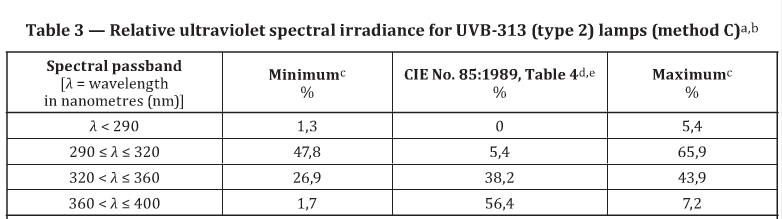

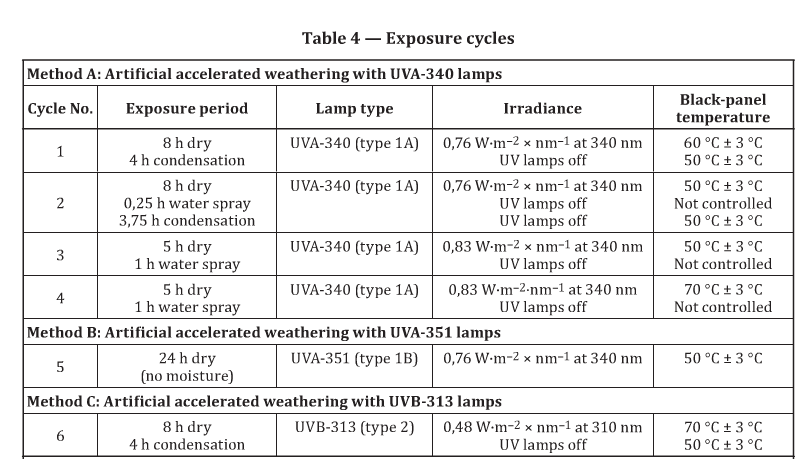

Fluorescent UV lamps are fluorescent lamps in which radiant in the ultraviolet region of the spectrum, i,e. below 400nm, makes up at least 80% of the total light output. There are three types of fluorescent UV lamp used in this part of ISO 4892.

UVA-340 these lamps have a radiant emission below 300nm of less than 1% of the less than 1% of the total light output, have an emission peak at 343nm, and are more commonly identified as UVA 340 for simulation of global solar radiation from 300nm to 340nm is a graph of spectral irradiance from 250 ~400nm.

UVA 351 lamps have a radiant emission below 310nm of less than 1% of the less than 1% of the total light output, have a peak emission at 353nm, and there are more commonly identified as UVA-351 for simulation of the UV Portion of solar radiation behind window glass,

UVB 313 these lamps are more commonly identified as UVB 313, and have a radiant emission below 300nm of less than 1% of the total light output, have a peak emission at 313nm.

The design of the exposure chamber may vary, but it shall be constructed from inert material and provide uniform irradiance in conformance with ISO 4892-1, with means for controlling the temperature.

When required, provision shall be made for the formation of condensate condensate or for spraying water on to the exposed faces of the specimens.

The use of a radiometer for irradiance control is recommend . If a radiometer is used, it shall conform to the requirement given in ISO 4892-1. If an automatic irradiance control system is not used, follow the apparatus manufacturer’s instruction on the procedure necessary to maintain the desired irradiance.

The test chamber shall be equipped with a means of producing intermittent condensation on, or directing intermittent water spray on to the front of the test specimens, under specified conditions. The condensate or spray shall be uniformly distributed over the specimens. The spray system shall be made from corrosion resistance material that do not contaminate the water employed.

Specimen holders shall made from inert material that will not affect the result of exposure. The behaviour of specimens can be affected by the presence of backing and by the backing material used. The use of backing shall therefore be by the mutual agreement between the interested parties.

It is recommend that at least three replicates of each material evaluated be sxposed in each test to allow statistical evaluation of the results.

For more details, please feel free to contact sales@lenpure.com

Or visit www.lenpure.com