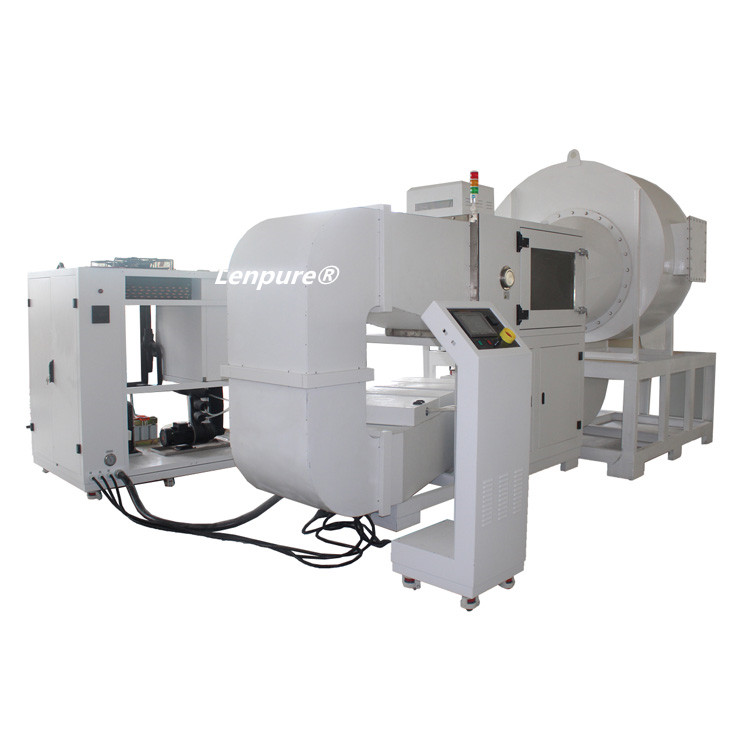

Model: LRHS-256-PS

Apply to: MIL-STD-810G Anti-dust Tests

Application: Military, Precision Instrument, etc.

Overview

Dual Blown Dust and Sand Test Chamber is used to evaluate all mechanical, optical, electrical, electronic, electrochemical and electromechanical devices liked to be exposed to dry blowing sand or dry blowing dust-laden atmospherse. It has two functions: Blowing Dust Test and Blowing Sand Test as per test standard MIL-STD-810G method 510.5.

Feature

● Blowing dust and blowing sand functions made on one-piece machine.

● Housing made of rugged stainless steels SUS304.

● Air flow uniform and steered.

● Toush-screen controller with data logging and download function

● Failure recording.

● Air velocity controllable.

● Dust or sand consentration controllable.

● Programmable controller with touch-screen display. Data logging and download.

● Rotational speed of rotary table is adjustable.

● Large viewing window for good vision.

● Cable Access Hole available.

● Tri-color Indicator and EMO(Emergency Off Switch) available.

● Dehumidification system

● Multiple protections on phase sequence, power leakage, etc.

● Easily accessible maintenance elements

Test Standard

MIL-STD-810G 510.5 Procedure I and Procedure II

| Size of Blown Dust and Sand Test Chamber | ||||

|

Model

|

Volume

|

Internal Dimension

D*W*H (mm) |

External Dimension

D*W*H (mm) |

Power

|

|

HLRHS-216-DS

|

216L

|

600 x 600 x 700

|

2000 x 4200 x 2200

|

45kW

|

| Specification | ||||

|

Performance

|

Temperature Range | 23°C~70°C | ||

| Temperature Deviation | ≤ ±2°C | |||

| Humidity | < 30%R.H | |||

| Air Velocity |

1.5 ~ 8.9 m/s (blown dust) 18.0 ~ 29.0 m/s (blown sand) |

|||

| Consentration |

3.0 ~ 17.6 g/m3 (10.7 ± 7 g/m3) - Blown dust 0.18 + 0.2 g/m3 -Blown sand 1.1 ± 0.3 g/m3 2.2 ± 0.5 g/m3 -Blown sand |

|||

|

Structure

|

External Casing | Cold-rolled A3 (Q235) steel plates with plastics painted. | ||

| Interior Working Room | Stainless Steel Plates SUS304 with miror surface | |||

| Air Circulation | Multiple-blades anti-abrasive blower | |||

| Dehumidification system | 0.7 Mpa air pressure, flow valume 10m3/h | |||

| Rotary Table | RMP and height is adjustable | |||

| Viewing Window | 300 x 300 mm big veiwing vision | |||

| Door | Manually operated sliding door with unlock button | |||

|

Control System

|

Controller | Programmable Touch-screen controller with data logging and download function | ||

| Water Storage | Failure recording and self-analysis | |||

| Safety Protection | Power leakage protection, over-load or over-current protection/Dry burning protection. | |||

| Voltage | AC220V/380V/440V±10%, 50Hz/60Hz or as per requirement | |||

Copyright(c) Shanghai Linpin 2011-2017 | Terms and Conditions | Privacy Policy | 沪ICP备07003980号-1 | 沪网安备31011209000148号