Climate Chambers for MIL-STD-750E: Salt Spray (Corrosion)

The salt spray corrosion environmental test chambers of Shanghai Linpin Instrument Stock Co., Ltd. is used to test the surface treatment of various meterials. The so-called treatments include coating, coating electroplating films of organic and non-organic materials, anodizing, anti-rest oil and corrosion resistant treatment, which may achieve the purpose of keeping the items from being corroded for a longer period.

1.Test of salt spray chamber and temperature requiretments of test:

| Test | NSS | ASS | CASS |

| Temperature of working room | approx 35°C | approx 35°C | approx 50°C |

| Temperature of air saturator | approx 47°C | approx 47°C | approx 63°C |

2.Spray Tower and funnel of salt spray chamber:

| Model | Quantity of Spray Tower | Quantity of Funnel |

| LRHS-108-RY | 1 | 1 |

| LRHS-270-RY | 1 | 2 |

| LRHS-412-RY | 1 | 2 |

| LRHS-663-RY | 2 | 2 |

| LRHS-816-RY | 2 | 2 |

| LRHS-1080-RY | 2 | 2 |

3. Factory configuration of salt spray chamber:

| Model | Configuration |

| LRHS-108-RY |

V-shaped Specimen Shelf x 4pcs, Round Bar x 8pcs, Nozzle x 2pcs, Funnel x 2pcs, Metering Cup x 2pcs, Exhaust pipe x 1pc*1m |

| LRHS-270-RY |

V-shaped Specimen Shelf x 6pcs, Round Bar x 12pcs, Nozzle x 2pcs, Funnel x 2pcs, Metering Cup x 2pcs, Exhaust pipe x 1pc*1m |

| LRHS-412-RY |

V-shaped Specimen Shelf x 8pcs, Round Bar x 16pcs, Nozzle x 2pcs, Funnel x 2pcs, Metering Cup x 2pcs, Exhaust pipe x 1pc*1m |

| LRHS-663-RY |

V-shaped Specimen Shelf x 8pcs, Round Bar x 16pcs, Nozzle x 3pcs, Funnel x 2pcs, Metering Cup x 2pcs, Triplet x 3pcs, Exhaust pipe x 2pcs*1m |

| LRHS-816-RY |

V-shaped Specimen Shelf x 10pcs , Round Bar x 20pcs, Nozzle x 3pcs, Funnel x 2pcs, Metering Cup x 2pcs, Triplet x 3pcs, Exhaust pipe x 2pcs*1m |

| LRHS-1080-RY |

V-shaped Specimen Shelf x 10pcs , Round Bar x 20pcs, Nozzle x 3pcs, Funnel x 2pcs, Metering Cup x 2pcs, Triplet x 3pcs, Exhaust pipe x 2pcs*1m |

4.Castors of salt spray chamber:

| Model | Castor |

| LRHS-108-RY | No casters, so it can't push away, Total weight is 65kg, it can be carried by two people. |

| LRHS-270-412-663-816-1080-RY | There are four casters, therefore, it can push away by people. |

5.Opening method of salt spray chamber:

| Model | Opening method |

| LRHS-108-270-RY | 108 and 270 are manual |

| LRHS-412-RY | 412 is a gas spring method |

| LRHS-663-816-1080-RY | 663, 816, 1080 is the cylinder opening |

6.The preparing before using salt spray chamber:

The machine we send to our customer has almost already installed well. The rest item customer need to prepare have 3 points:

1).Purified/Distilled/Deionized water.

2).Salt solution.

Take ASTM B117 test standard as a reference: The salt solution shall be prepared by dissolving 5±1 parts by mass of sodium chloride in 95 parts of water. We could match the salt solution accordingly to the Nacl concentration as 50g±5g/L

Different test method has different way for matching solute, then to change the PH valve, finally to reach different accelerated solution effect.

—For Neutral Salt Spray Test (NSS), the PH value is 6.5~7.2 / 50g±5g/L Nacl concentration.

—For Acetic Acid Salt Spray Test (AASS), it bases on 50g±5g/L Nacl concentration

of NSS, then adding some glacial acetic acid, and stirring evenly and finally making the PH value for 3.0~3.1.

—For Copper Accelerated Acetic Salt Spray Test(CASS), It based on AASS, to add some Copper Chloride, its concentration is 0.26g/L±0.02g/L, and finally to stir until the Nacl and Copper Chloride dissolve completely. Finally to add less glacial acetic acid, then stirring evenly and making its PH value to 3.0~3.1.

3). Air compressor.

Air compressor is providing inlet pressure to the chamber. We suggest customer to adjust to 0.2~0.4Mpa.

7.Five places in the salt spray chamber with water:

Saturated air tank: pure water or distilled water

Brine preheating tank and brine tank: salt solution;

Studio: pure water;

Sealing tank: pure water.

8.Main safety protection for salt spray chamber:

1). Over temperature protection for the chamber and the saturator barrel

The chamber intalled 2 over temperature protector, one for the chamber, other for the saturator barrel. We set the protection temperature separately, the probes will sense the temperature in the chamber and saturator barrels separately, if over the setting one will produce alarm, and the machine stop running.

2). Low water level protection for the the chamber,the saturator barrel and salt water barrel.

If the water lever of the chamber and the saturator barrel is too low, it will produce alarm, and machine stop running.

3). Dry burn protection of the heating pipe.

If without water on the button of the chamber, and the situation of heating pipe dry burn happened, it will produce alarm, and machine stop running.

4). Lacking air protection.

When make salt spray test, if without the air coming from the air compressor or the inlet pressure is very small. It will produce alarm, and machine stop running.

9.Heating method of salt spray chamber:

Water-bath heating, a space-grade titanium heating tube is installed at the bottom of the salt spray chamber, which can heat the water in the working chamber to the set value. According to the test standard, there is also dry heating.

10.Spray method of salt spray chamber:

Spray method of salt spray chamber can be sprayed before stopping or stopping before spraying.

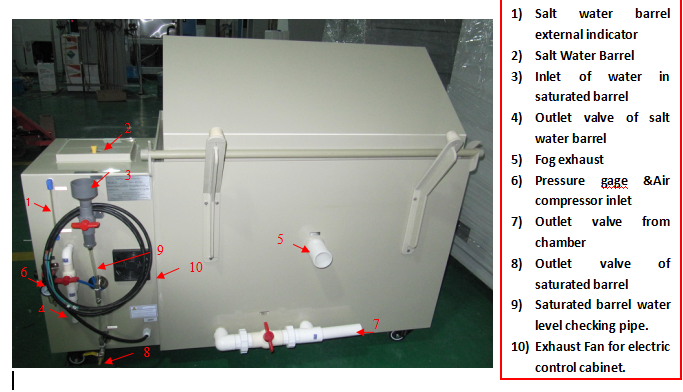

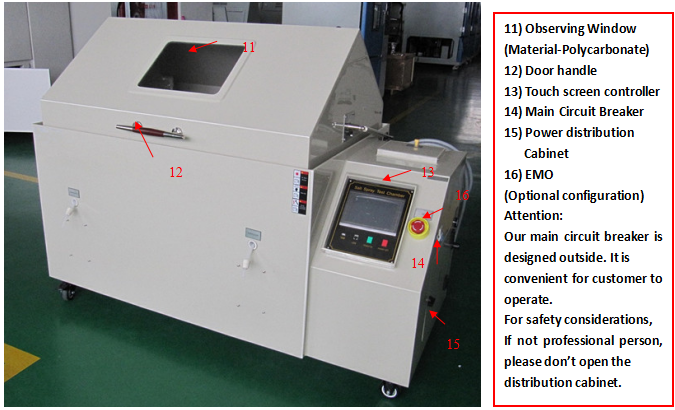

11.Basic structure of salt spray chamber

This test is proposed as an accelerated laboratory corrosion test simulating the effects of seacoast atmosphere on devices. This test can also be used to detect the presence of free iron contaminating the surface or another metal, by inspection of the corrosion products.

Apparatus used in the salt-spray test shall include the following:

a. Exposure chamber with racks for supporting specimens.

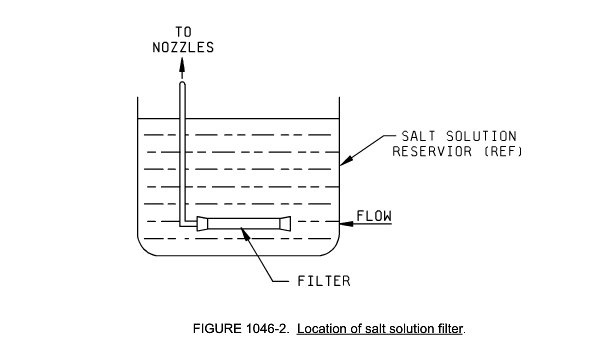

b. Salt-solution reservoir with means for monitoring an adequate level of solution.

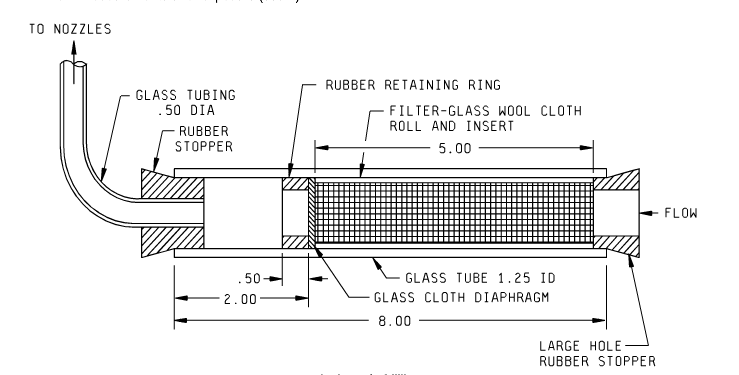

c. Means for atomizing the salt solution, including suitable nozzles and compressed-air supply.

d. Chamber-heating means and control.

e. Means for humidifying the air at a temperature above the chamber temperature.

Test procedure, the following exceptions shall apply:

a. At the conclusion of the test, the device will be dried for 24 hours at +40C ±5°C before the examination. A device with illegible marking, evidence (when examined without magnification) of flaking or pitting of the finish or corrosion that will interfere with the application of the device shall be considered a failure.

b. Unless otherwise specified, salt solution shall be 20 percent by weight.

Temperature Range:

The test shall be conducted with a temperature in the exposure zone maintained at +35°C +1.1°C,-1.7°C.

Atomization:

The conditions maintained in all parts of the exposure zone shall be such that a suitable receptacle placed at any point in the exposure zone will collect from 0.5 to 3.0 millliiters of solution per hour for each 80 square centimeters of horizontal collecting area (10 centimeters diameter) based on an average run of at least 16 ours.

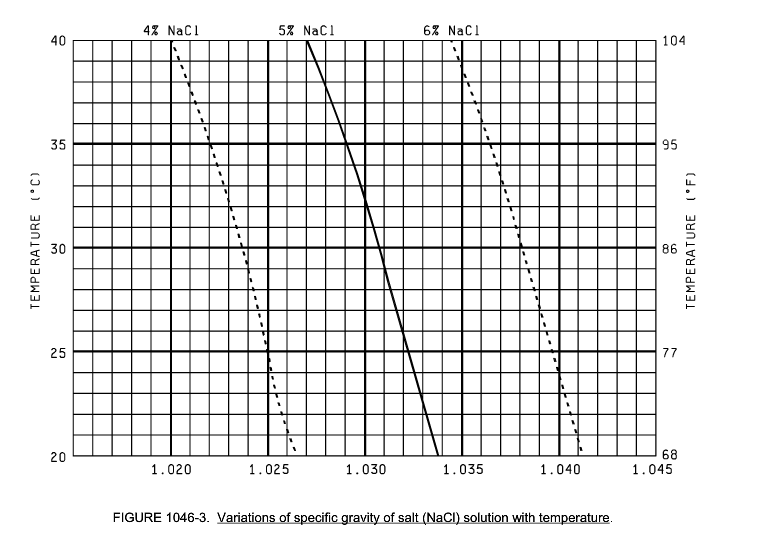

The 5-percent solution thus collected shall have a sodium-chloride content of from 4 to 6 percent (specific gravity) in accordance with figure 1046-3 when measured at a temperature between +93F and +97F (+33.9C and +36.1C).

At least two clean fog-collecting receptacles shall be used, one placed near any nozzle and one placed as far as possible from all nozzles. Receptacles shall be fastened so that they are not shielded by specimens and so that no drops of solution from specimens or other sources will be collected.

The specific gravity and quantity of the solution collected shall be checked following each salt-spay test. Suitable atomization has been obtained in boxes having a volume of less than 12 cubic feet with the following conditions:

a. Nozzle pressure of from 12 to 18 pounds per square inch.

b. Orifices of from .02 to .03 inch in (0.508 to 0.762 mm) diameter.

c. Atomization of approximately 3 quarts of the salt solution per 10 cubic feet of box volume per 24 hours.

When using large-size boxes having a volume considerably in excess of 12 cubic feet, the above conditions may have to be modified in order to meet the requirements for operating conditions.

Length of test:

a.96 hours

b.48 hours

If you are still interested in any kind of environmental test chambers, and I'm pleased provide some of our details and project to you. That's more, at present we have more attractive price for you. Welcome for inquiry any time, I will reply asap!

If you want to know more information about climate chambers or Shanghai Linpin, please feel free to contact sales@lenpure.com or visit http://www.lenpure.com/ .