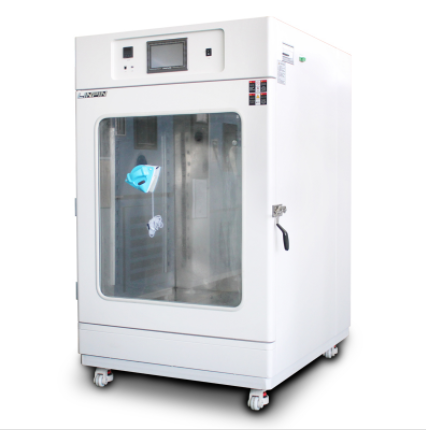

Climate Chambers for BS 3900 F2 Methods of Test for paints

Lenpure Programmable Water Condensation Environmental Test Chambers give the maximum durability and performance for your most demanding test requirements.It is the necessary test equipment for aviation, Aerospace, automotive, electronics, military and solar panel industry etc.It can be used to test and determine the parameters and performance of electrical, electronic products and materials in the most extreme temperature and humidity conditions.

The method of test described below requires to be completed, for any particular application, by the following supplementary information. This information is to be derived from the British Standard or other document for the product under test or, where appropriate, is to be the subject of agreement between the parties to the test.

1) Material and surface preparation of substrate.

2) Method of application of test coating to substrate.

3) Thickness, in micrometres, of dry coating, including method of measurement in accordance with BS 3900-C51) and whether it is a single coat film or a multicoat system.

4) Duration and conditions of drying of the coated panel before testing (or conditions of stoving and ageing, if applicable) before testing.

5) Duration of test.

6) How inspection of the test coating is to be made and what characteristics are to be considered in evaluating its resistance properties.

Apparatus

3.1 The apparatus shall consist of a closed cabinet in which the relative humidity is maintained at approximately 100 % and the temperature is cycled continuously over the range 42 C to 48 C. thereby ensuring that copious condensation occurs on test panels positioned vertically within the cabinet.

NOTE If the cabinet is copper lined, the copper should be tinned or coated with a suitable organic coating to prevent the solution of small amounts of copper in the water.

3.2 The design and dimensions of the apparatus are left to the user's discretion, provided that the following conditions are observed.

3.2.1 Humidification. The humidity shall be maintained by evaporation of distilled water2) from a reservoir covering (or situated in) the bottom of the cabinet. The water shall be maintained free from grease or oil.

3.2.2 Heating. The cabinet shall be heated through he medium of the water by a heater placed immediately below the water reservoir or, alternatively, by a heater completely immersed in the water.

3.2.3 Temperature cycle. The heater shall be controlled by two thermostats (placed in the air pace above the water) in such a way that the temperature of the air space is cycled continuously from 42 C to 48 C and back to 42 ℃ in 60 ± 5 minutes.

The times required for heating and cooling shall be approximately equal. A recording thermometer is desirable for ensuring that the temperature cycle is correct.

3.2.4 Air circulation. The air in the cabinet shall be circulated by means of a fan in such a way that the temperatures at any two points in the air space do not differ by more than 1.0 C at any given moment.

3.2.5 Spacing of panels. With cabinets as usually constructed, it is inadvisable to place the panels less than 40 mm apart or less than 40 mm from any side of the cabinet.

3.2.6 Suspension of panels. If the panels hang in the cabinet, it is essential that the hooks and rods from which they are suspended shall be made of glass or plastics material. If racks are used, the panels shall stand vertically and be suitably insulated from any metal parts.The position of the panels in the cabinet shall be interchanged throughout the test period, once every 24 hours.

NOTE The cabinet should be opened only at intervals of 24 hours, for inspection of panels, maintenance of the water level, rotation of panels, ete.

5 Test panel

5.1 Materials and dimensions

Unless otherwise specified or agreed the test panel shall be of burnished steel complying with the requirements of .BS 3900-A35), of approximate dimensions 150 mm x 100 mm x 1.25 mm.

NOTE Results of tests carried out on different substrates do not necessarily correlate with each other.

5.2 Preparation and coating of test panel

The test panel shall be prepared in accordance with BS 3900-A3,6) unless otherwise specified, and shall then be coated by the specified method with the product or system under test in accordance with BS 3900-A47),The back and edges of the panel shall also be coated using a good quality protective paint not containing zinc chromate or any similarly water-soluble pigment.

5.3 Drying of test panel

The coated panel shall be dried (or stored) for the specified time and under the specified conditions and, unless otherwise specified shall be conditioned at a temperature of 23±2℃C and relative humidity of 50 ±5 % for a minimum of 16 hours, with free circulation of air and not exposed to direct sunlight

5.4 Thickness of coating

The thickness of the dry coating shall be determined by the method specified.in accordance with BS 3900-C58)

6 Procedure

6.1 General

The test procedure shall be carried out immediately upon completion of the conditioning period.

6.2 Exposure procedure

Expose the panel in the cabinet for the specified period.

6.3 Interim inspections. For interim inspections during the test period, if specified, the panel shall be removed from the cabinet, blotted with absorbent paper, examined for blistering or other signs of deterioration and immediately returned to the cabinet.

6.4 Final inspection

At the end of the specified test period, remove the panel from the cabinet, blot it with absorbent paper and immediately examine the whole test surface for blistering or other signs of deterioration.

Allow the panel to stand at room temperature for 24 hours and examine the test surface again for loss of adhesion, rust staining change of colour, embrittlement or other characteristics which may be specified Carefully remove a 150 mm × 50 mm strip from the test surface with a non-corrosive paint remover9) and examine the exposed metal for signs of corrosion. Where panels are required to be kept for reference purposes the exposed area shall be protected by a suitable transparent lacquer.

If you are still interested in any kind of environmental test chambers, and I'm pleased provide some of our details and project to you. That's more, at present we have more attractive price for you. Welcome for inquiry any time, I will reply asap!

If you want to know more information about climate chambers or our company, please feel free to contact sales@lenpure.com or visit http://www.lenpure.com/ .