Climatic chambers for test standard BS 3900 F15

There is seldom a direct relationship between the resistance of organic coatings to the action of humidity and the resistance to deterioration in other environments. This is because the effect of each of the several factors influencing the progress of deterioration varies greatly with the conditions encountered. This standard needs a climatic chamber--Water Condensation Test Chamber.

Therefore, the results obtained in this test should not be regarded as a direct guide to the resistance of the tested coatings in all environments where these coatings may be used. Also, performance of different coatings in the test should not be taken as a direct guide to the relative performance of these coatings in service. Nevertheless, the method described gives a means of checking that the quality of a paint or paint system is being maintained.

This international standard is one of a series of standards dealing with the sampling and testing of paints, varnishes and related products. It specifies a test method for determining under standard conditions the resistance of a single coat or a multi-coat system of paint or related material to intermittent water condensation. The method includes the testing of coatings on non-porous and on porous substrates.

Coated specimen are placed in a cabinet or chamber containing a heated, saturated mixture of air and water vapour. The temperature of the cabinet or chamber is maintained at (40±3)℃. At 98% to 100% relative humidity, the very small temperature difference between the specimen and the surrounding vapour causes the formation of condensation on the specimens.

This is an intermittent condensation test and after a period of time under these conditions the conditions in the cabinet or chamber are cycled to give (23±5)℃ and (50±20)% relative humidity, i.e. dry conditions.

Water permeates the coating at rates that are dependent upon the characteristics of the coating. Any effects such as colour change, blistering, loss of adhesion, softening or embrittlement are observed and reported using criteria previously agreed between the interested parties, these criteria usually being of a subjective nature.

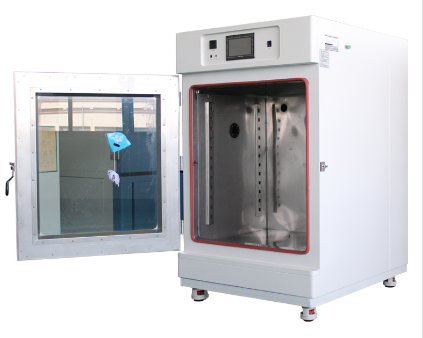

An airtight laboratory cabinet of capacity 300 litres or a larger chamber of capacity 1m³ or 2m³ up to a walk-in chamber shall be used.

Airtight cabinet, of capacity (300±10) litres, in the base of which is a watertight trough fitted with a means of heating the water to meet the requirement of test cycle.

The dimensions and design of the cabinet are not critical, provided the requirement of specimen-suspension/support equipment are met. It shall be constructed of an insert material and have a roof which prevents condensed moisture dripping on to the test specimens. The cabinet shall be provided with a means of relieving excess pressure. The cabinet shall also be provided with a means of controlling the temperature, which shall be measured in the space above the test specimens.

Airtight chamber, constructed of an inert material, with a window formed by two sheets of glass or other transparent material at a distance of 10mm or more and with a roof which prevents condensed moisture dripping on to the test specimens. The chamber shall be provided with a means of relieving excess pressure. Insulation of the enclosure is not required.

In the base of the chamber is a watertight trough filled with heated water to a depth of at least 10min. The lateral dimension of the trough shall correspond to the area used to expose the test specimens. The chamber shall be provided with a door or a removable hood. If a walk-in chamber is used, it shall be provided with a ventilator and an air outlet capable of generating about 10 air changes per hour.

Heated water tank, outside the test chamber, connected to the trough, a pump, a supply of water of grade 2 quality as defined in ISO 3696, and a water-level control. The pump shall be capable of changing the water in the trough about four times per hour to meet the requirements of 8.4.

Thermostatic-control unit for the heater in the water tank, with the sensor located in the middle of the chamber at the uppermost specimen-exposure level. Thermometer, with its sensor located adjacent to the thermostatic control sensor. If a walk-in chamber is used, it is preferable to install more than one thermometer and have the reading permanently recorded.

Specimen-suspension/support equipment. Test panels shall normally be suspended, using synthetic-fibre or other insert insulating material. If, however, the test panels are exposed in racks, the racks shall be made of insert material and shall on no account impede the free convection of the air/water-vapour mixture. By agreement between the interested parties, painted specimens of different shapes may be exposed.

These specimens shall be exposed in their normal attitude in use. Test panels shall be exposed vertically at least 100mm from any wall or cover, at least 20mm from each other and with the lower edges of the panels at least 200mm above the water. Panels should preferably be placed at one level within the cabinet or chamber. In any case, care shall be taken to ensure that water which condenses on the upper panels does not drip on to the lower panels.

Coated specimens, including panels, including panels, with dimensions larger than those specified in 7.1.1 shall be exposed so that their lower edges are above the lowest level that gives condensation. It may be necessary to place the specimen in the upper part of the cabinet as the temperature differences at the lower levels may be too small to induce condensation.

Environmental cabinet, capable of being maintained at a temperature of (23±5)℃ and a relative humidity of (50±20)%, and including a stand for test panels. Take a representative sample of the product to be tested (or of each product in the case of a multi-coat system), as described in ISO 1512. Examine and prepare each sample for testing, as described in ISO 1513.

For more details, please feel free to contact sales@lenpure.com

Please visit www.lenpure.com