Model:101/225/504/800/1000L

Apply to:Cryogenic Test

Application:Aerospace,automotive,electronics,pharmaceuticals industry etc.

Overview

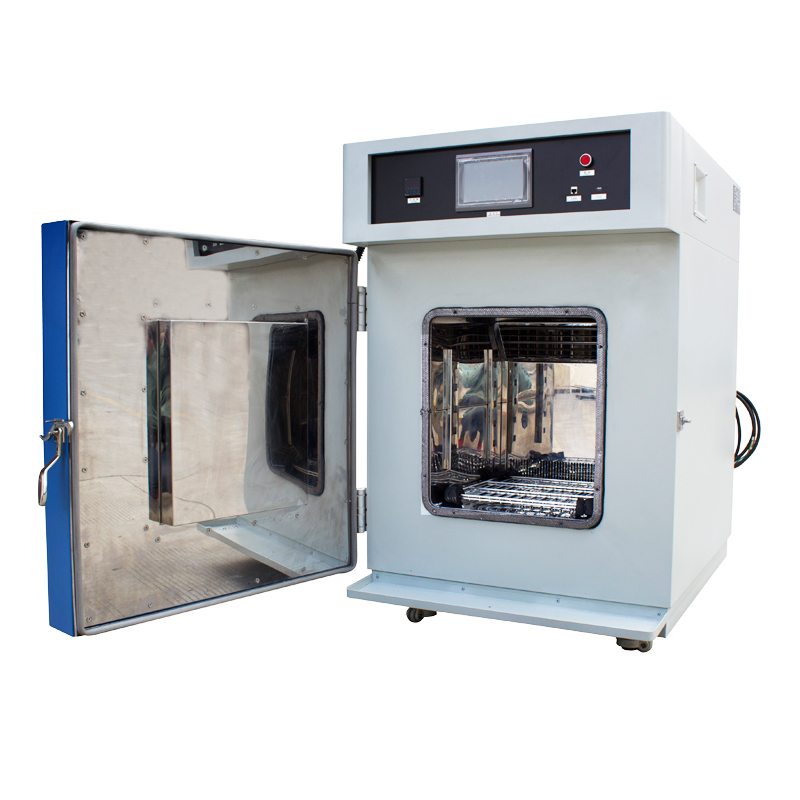

Lenpure Ultra Low Temperature Chamber give the maximum durability and performance for your most demanding test requirements.It is the necessary test equipment for aviation, Aerospace, automotive, electronics, military and solar panel industry etc.It can be used to test and determine the parameters and performance of electrical, electronic products and materials in the most extreme temperature and humidity conditions.

Feature

●Programmable Touch Screen Controller

●Custom Sizes Available

●Running Time Meter

●Capable of Handling Extreme Temperature

●High Performance Even Under Load

●Incandescent Interior Lighting

●Modular,Robust Reliable Construction

●Stainless Steel Interior

●Painted Galvanized Steel Exterior For Long Life

●Heavy-duty Flooring to Support Vehicles

●Mechanical Cooling

●Comprehensive Safety Features

●Refrigeration Gauges

●Refrigeration Sound Deadening Package

●All Circuits Fused or Circuit Breaker Protected.

●All Wiring Numbered or Color Coded

●Compressor Overload Protection

●Prefabricated for On-Site Installation

Test Standards

This test equipment conforms to following test standards (but not limited to):

●IEC60068-2-1

●IEC60068-2-2

●IEC60068-2-78

●IEC60068-2-30

| Sizes of Cryogenic Chambers | |||||

|

Model

|

Volume (L)

|

Temperature Range

(°C) |

Rated Power

|

Internal Dimension (mm) D*W*H

|

External Dimension (mm) D*W*H

|

|

LRHS-101-YD

|

101

|

﹣196℃~RT

|

2.5kw

|

450*450*500

|

1100*900*1350

|

|

LRHS-225-YD

|

225

|

3.0kw

|

500*600*750

|

1150*1100*1600

|

|

|

LRHS-504-YD

|

504

|

4.2kw

|

700*800*900

|

1350*1300*1750

|

|

|

LRHS-800-YD

|

800

|

6.2kw

|

800*1000*1000

|

1450*1500*1850

|

|

|

LRHS-1000-YD

|

1000

|

6.2kw

|

1000*1000*1000

|

1450*1500*1850

|

|

|

Note: In the Model, the number means volume of test chamber's working room. For example, model LRHS-101-YD means the volume of this test chamber is 101L. LRHS-225-YD means the volume is 225L |

|||||

| Basic Specification | |||||

|

Performance

|

Temperature Range | -196℃~RT | |||

| Temperature Fluctuation | ≤1.0°C | ||||

| Temperature Uniformity | ±2.0°C | ||||

| Ramp Rate |

≥3°C/min Note: can be customized as per requirement |

||||

|

Material

|

External Casing | Cold-rolled A3 (Q235) steel plates with plastics painted. | |||

| Interior Working Room | Stainless Steel Plates SUS304 with miror surface | ||||

| Heat Isolation | Polyurethane foams and fine glass fibres | ||||

| Illumination Lamp | Philips® one in per standard test chamber. | ||||

| Casters | 4pcs, with PU covered for protection. Height adjustable and direction universal. | ||||

| Door | Manually operated sliding door with unlock button | ||||

|

Heating & Cooling System

|

Heater | Steipped Nickel-chromium Wire Heater | |||

| Air Blower | Anti-temperature stainless fan blades with low noise | ||||

| Compressor | Hermetically-sealed Techmesh® or semi-sealed Bitzer® or GEA® or equivalent compressors | ||||

| Cooling Method | Single or dual cooling (Air-cooled or Water-cooled) | ||||

| Refrigerant | Liquid Nitrogen | ||||

| Condenser | Plate-type heat exchanger | ||||

|

Control System

|

Controller |

7" Programmable colorful touch-screen display LCD English Display Microcomputer integrated controller |

|||

| Functions | Data Record (Max 600 days x 24hrs), History Curve, USB data download & upload, Remote controlling through PC, Automatic protection alarms, etc. | ||||

| Program |

1~1000 programs, 1~999 steps for per program, Max 99hrs 59mins for per program. 10 programs can be interli |

||||

| Temperature Sensor | Platinum Resistance.PT100Ω | ||||

| Running Model | Constant/Fix-value Model and Programmable Model | ||||

| I/O Interface | Communicate port (RS485) to connect test chamber to a PC | ||||

| Standard Configuration | Test Chamber x 1, Specimen Holder Shelf x 2, φ100mm Cable Access Port x 1 with 1 soft plug, EMO x 1, Tri-color Indicator x 1, etc. | ||||

| Safety Protection | Power leakage protection/Compressor over-heat, over-load or over-current protection/Dry burning protection. | ||||

| Voltage | AC220V/380V/440V±10%, 50Hz/60Hz or as per requirement | ||||

| Ambient Enviromental for application | 5°C~+30°C ≤ 85%R.H | ||||

| Test Standards (not limited to) |

IEC60068-2-1

IEC60068-2-2

IEC60068-2-78

IEC60068-2-30

|

||||

Copyright(c) Shanghai Linpin 2011-2017 | Terms and Conditions | Privacy Policy | 沪ICP备12029585号 | 沪网安备31011209000148号