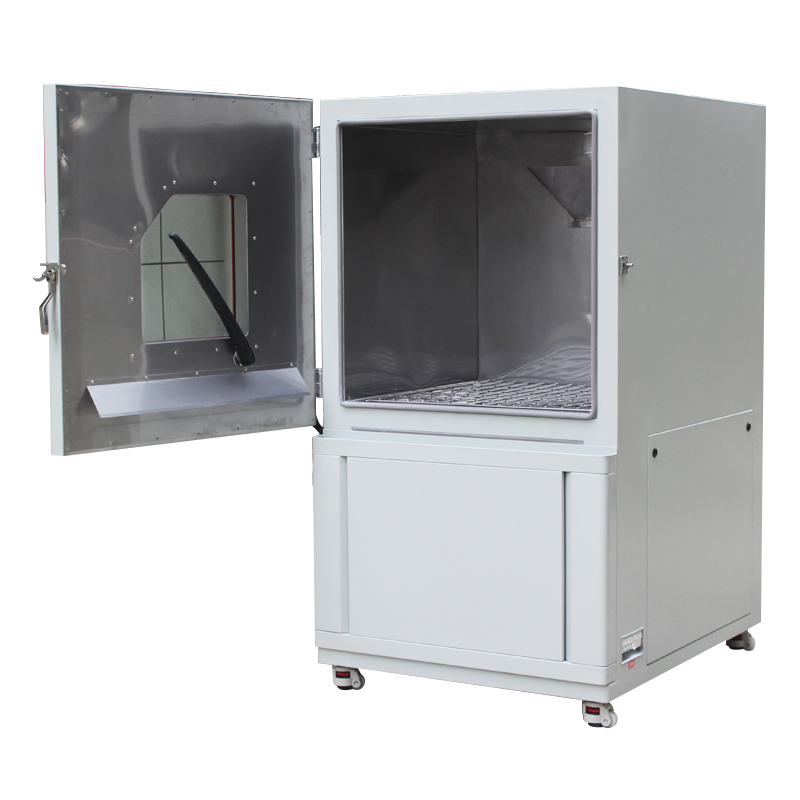

Model: 512L/800L/1000L/1500L

Apply to: IP5X IP6X Dustproof Tests

Application: Enclosures, Automotive Parts, Electronics, LED lights, etc.

Overview

Dust and Sand Test Chamber has used in the test the sealing property of product's housing.It is mainly applied for IP5X and IP6X these 2 grade's test. It mainly simulates the damage to lock, automobile part, sealing element, display etc. product in the sand and dust storm weather.

Feature

● Air velocity sensor inside chamber

● Programmable controller with touch-screen display. Data logging and download.

● Full-Opening Front Loading Door

● 3” Thick Foam Insulation

● Tri-color Indicator and EMO (Emergency off switch)

● Cable Access Port Holes (diameter50&100 mm)

● Interior lights

● All wires numbered for easy identification

● Easy-to-operate models.

● Fixable and movable casters with great convenience.

● Multiple protections on phase sequence, power leakage, etc.

● Easily accessible maintenance elements.

● Operation : Program or manual

Test Standards

This test equipment conforms to following test standards (but not limited to):

●GB 4208-2008

●IEC 60529

●GJB 150.12A-2009

●GJB150.12-86

| Sizes of Dust Test Chamber | ||||

|

Model

|

Volume (L)

|

Rated Power

|

Internal Dimension (mm) D*W*H

|

External Dimension (mm) D*W*H

|

|

LRHS-512-PS

|

512

|

2.5kw

|

800*800*800

|

1300*1050*1750

|

|

LRHS-800-PS

|

800

|

2.5kw

|

800*1000*1000

|

1300*1250*1950

|

|

LRHS-1000-PS

|

1000

|

2.5kw

|

1000*1000*1000

|

1600*1250*1980

|

|

LRHS-1500-PS

|

1500

|

2.5kw

|

1000*1500*1000

|

1600*1750*1980

|

| Basic Specification | ||||

|

Performance

|

Air speed | Not Exceed 2m/s Lowing | ||

| Time setting Range | 1~999H adjustable | |||

| Sand and dust concentration | 2~4kg/m3 | |||

| Test Dust | Dry Talcum powder,Silicate cement,smoke ash,etc. | |||

| Vacuum pump flow control | 60~600L/H | |||

| Dust method | continous.period blowing dust time setting is optional | |||

|

Structure

|

External Casing | Cold-rolled A3 (Q235) steel plates with plastics painted. | ||

| Interior Working Room | Stainless Steel Plates SUS304 with miror surface | |||

| Heat Isolation | Polyurethane foams and fine glass fibres | |||

| Viewing Window | Toughened glass with conductive films for heating to defrost(395×395mm) | |||

| Door | Manually operated sliding door with unlock button | |||

|

Control System

|

Controller | Programmable Touch-screen controller “weinview” with data logging and download function | ||

| Heating System | Steipped Nickel-chromium Wire Heater | |||

| Dust dehumidification | Heating and dehumidification | |||

| Vibration time | 1S-99H adjustable | |||

| Blowing time | 1S-99H adjustable | |||

| Cycle time | Arbitrarily set the blowing time | |||

| Dust heat | Use stainless steel Mica Heating coil constant control to prevent dust adhesion | |||

| Standard Configuration | Test Chamber x 1,Dust scraperx 1, talcum powder x 100g , EMO x 1, Tri-color Indicator x 1, etc. | |||

| Safety Protection | Power leakage protection, over-load or over-current protection/Fan motor overheating/Dry burning protection. | |||

| Voltage | AC220V/380V/440V±10%, 50Hz/60Hz or as per requirement | |||

| Ambient Enviromental for application | 5°C~+30°C ≤ 85%R.H | |||

| Test Standards (not limited to) | IEC 60529 IP5X IP6X | |||

Copyright(c) Shanghai Linpin 2011-2017 | Terms and Conditions | Privacy Policy | 沪ICP备12029585号 | 沪网安备31011209000148号