Model:101L/225L/504L/800L/1000L

Apply to:High Temperature Aging Test

Application:Cable,Electronic parts , Plastic,Rubber,me

Overview

Lenpure Air ventilation Aging Test Chamber It is suitable for the thermal endurance test of electrical insulating materials and the air exchange aging test of electronic parts and components as well as plastic products. Test and judge the adaptability of products when stored and used in high-temperature environmental conditions; measure the properties of test specimens upon aging in high-temperature and barometric air and compare the results with that of the un-aged test specimens

Features

▪ 100L to 1000L capacity optional and customized size available .

▪ Wide temperature range

▪ Small temperature spread–even when loaded

▪ Incorporated with protection module for safety voltage

▪ Heavy-duty flooring to support vehicles

▪ All circuits fused or circuit breaker protected.

▪ Incandescent interior lighting

▪ Painted galvanized steel exterior for long life

▪ Tri-color Indicator and EMO (Emergency-off Switch) available.

Test Standards

▪ ASTM D 1171 , ASTM D 1149

▪ DIN/EN 27326 , DIN 53509

▪ UL-1581

▪ JB/T 7444-94

This test equipment comply with above test standards (but not limited to)

|

Model

|

Volume (L)

|

Temperature Range

(°C) |

Rated Power

|

Internal Dimension (mm) D*W*H

|

External Dimension (mm) D*W*H

|

|

LRHS-101-NHQ

|

101

|

RT+10°C ~ 200°C+

|

4.0kw

|

450*450*500

|

730*1180*1480

|

|

LRHS-225-NHQ

|

225

|

6.5kw

|

500*600*750

|

780*1330*1730

|

|

|

LRHS-504-NHQ

|

504

|

7.5kw

|

700*800*900

|

1020*1430*1880

|

|

|

LRHS-800-NHQ

|

800

|

9.0kw

|

800*1000*1000

|

1100*1730*1980

|

|

|

LRHS-1000-NHQ

|

1000

|

9.5kw

|

1000*1000*1000

|

1300*1730*1980

|

|

| Basic Specification | |||||

|

Performance

|

Temperature Range | RT+10°C ~ 200°C/300°C | |||

| Temperature Fluctuation | ±0.5°C | ||||

| Temperature Uniformity | ≤ 2%°C | ||||

| Temperature change speed | 1.0~3.0°C/Min | ||||

| Air Ventilation Volume | RT+10℃~200℃ 10-200Times/H 201℃~300℃ 10-150Times/H | ||||

| Inlet/Exhaust control | scale indication , adjustable | ||||

| Ventilation Time | 1m ~ 99h , adjustable | ||||

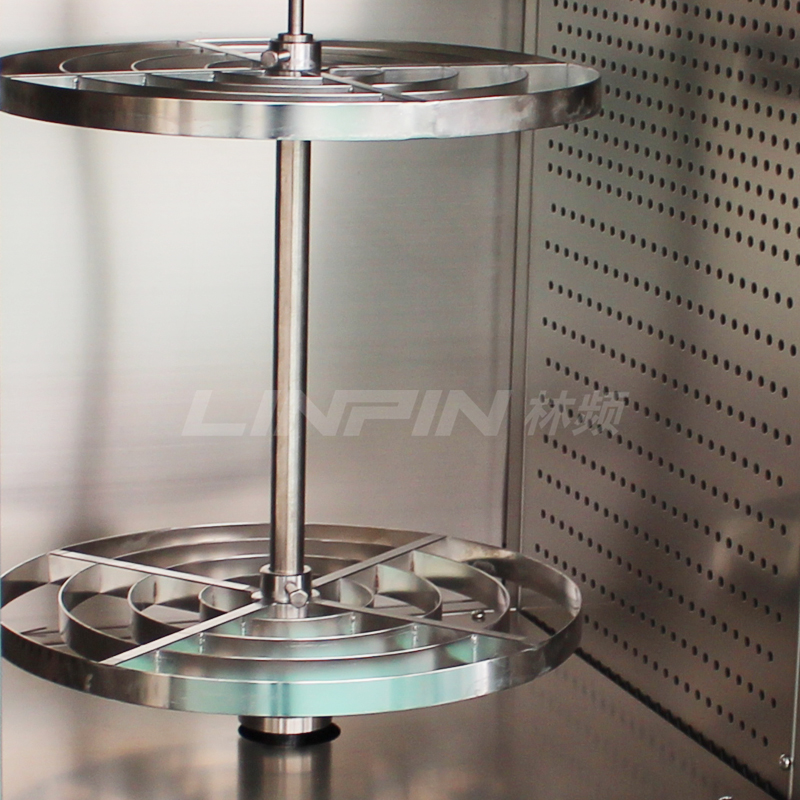

| Rotary Holder |

2 la |

||||

|

Material

|

External Casing | Cold-rolled A3 (Q235) steel plates with plastics painted. | |||

| Interior Working Room | Stainless Steel Plates SUS304 with miror surface | ||||

| Heat Isolation | Polyurethane foams and fine glass fibres | ||||

| Illumination Lamp | Philips® one in per standard test chamber. | ||||

| Casters | 4pcs, with PU covered for protection. Height adjustable and direction universal. | ||||

| Viewing Window |

Multi-la |

||||

| Door | Manually operated sliding door with unlock button | ||||

|

Control System

|

Heater | Steipped Nickel-chromium Wire Heater | |||

| Controller | Samwon ST190 Microcomputer integrated controller | ||||

| Temperature Sensor | Platinum Resistance.PT100Ω | ||||

| Standard Configuration | Test Chamber x 1, Specimen Holder platform x 1 | ||||

| Safety Protection | Power leakage protection, over-load or over-current protection/Dry burning protection. | ||||

| Voltage | AC220V/380V/440V±10%, 50Hz/60Hz or as per requirement | ||||

| Ambient Enviromental for application | 5°C~+30°C ≤ 85% R.H | ||||

Copyright(c) Shanghai Linpin 2011-2017 | Terms and Conditions | Privacy Policy | 沪ICP备12029585号 | 沪网安备31011209000148号