Climatic chambers DIN EN-61747-5 environmental endurance test

Lenpure climatic chambers is a reliable and professional high-tech enterprise in the field of environmental chambers. As an expert test chambers manufacturer and a comprehensive one-stop solution service provider. Lenpure owns its standardized production bases and showrooms.

Lenpure is a famous brand in environmental test chambers, which has so many advantages.

Lenpure owns its standardized production bases and showrooms.

Strategic cooperation with Shanghai Jiaotong University.This university specialized in temperature filed for 42 years, the lowest temperature reaches to -220oC by liquid nitrogen. Unique technology in China, advanced in the world.

Unique joint-stock high-tech enterprise of China in the filed.

Unique China enterprise gets Measurement Standards Certificate from Shanghai Quality and Technical Supervision in the filed.

Unique China enterprise in the filed reported by CCTV ( China Central Television )

l39 software copyrights and 156 national technology patents & invention patent. CE certification.Independent Import & Export right.

lISO9001:2008 QMSC (quality management system certification); ISO14001:2004 Environment Management System Certification;

GB/T28001-2001 Occupational Health and Safety Management System Certification;

l100% passing rate inspected by Shanghai Institute of Metrology and measurement technology or other recognized third-party organizations.

We are the nominated supplier of CASC (China Aerospace Science and Technology Corporation), CAS (Chinese Academy of Sciences), and many other top 500 enterprises

Lenpure products have meet so many international test standards which can meet requirements indifferent filed and the countries all over the world.

DIN EN-61747-5 introduce Environmental, endurance and mechanical test methods of Liquid crystal and solid-state display devices.

1. Atmospheric environmental conditions are below

temperature:15~35℃.

Humidity 25% ~ 85%

Pressure 96 kpa ~ 106 kpa

2. Environmental and durability test methods.

2.1 Rapid temperature change

The absolute humidity of the atmosphere should not exceed 20 g / m³

The high temperature range of test temperature can be choose from 30~100 ℃and the low temperature range can be choose is -15~-50 ℃。

The exposure time T1 of each temperature at two temperatures depends on the thermal capacity of the device. According to the relevant specifications, it should be 3h, 2h, 1h, 30 min, 10min, and if the relevant specification is not specified, it should be 3h.

Select the conversion time T2. Depending on the thermal time constant of the test sample, the conversion time should be 2 min~3min, 20 s ≤ 30 s, less than 10 s.

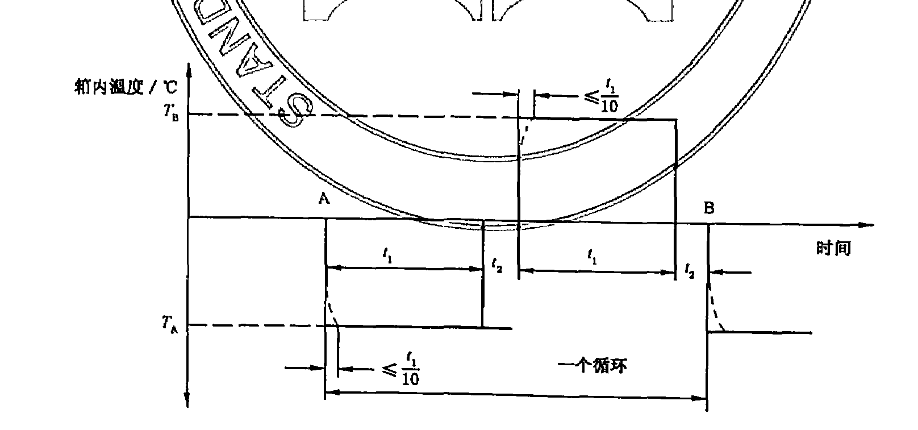

The first cycle consists of two exposure times T1 and two conversion times T2, as shown in the figure below. The number of cycles should be 5 or 10.。

2. Description of temperature and humidity cycle

a) the temperature of the test chamber shall be within 1.5h ~ 2.5h and shall be continuous to the specified high temperature, during which the relative humidity shall be kept within (93±3)%.

b) within 5.5h after the beginning of the cycle, the temperature and relative humidity in the box shall be kept at the prescribed high temperature and (93±3)% respectively.

c) the temperature of the test chamber shall be reduced to 25 ℃±2℃ within 1.5h-2.5h, during which the relative humidity shall be kept within the range of 80%~ 96%.

d) From 8h after the beginning of the cycle, the temperature of the test chamber shall rise continuously to the specified high temperature within 1.5h ~ 2.5h, during which the relative humidity shall be kept within (93±3)%.) from the beginning of the cycle until 13.5 h,

e) the temperature and relative humidity in the tank shall be kept at the specified high temperature and (93±3)%, respectively

f) the temperature of the test chamber should be reduced to 25 ℃±2℃ within 1.5h ~ 2.5h, during which the relative humidity should be kept within the range of 80%~ 98%.

g) the temperature in the test box should remain stable at 25 ℃±2℃ and the relative humidity (93±3)% until the low temperature cycle starts or the 24h cycle ends.

Before you do the above test, the installation is very important. Then show you how to operate the climatic rapid change temperature chambers.

When installing the Lenpure test chamber, the outer Chamber of the chamber shall be grounded, otherwise, the risk of electric shock may occur due to leakage.

Don't run the equipment and carry out the test until it is installed reliably.

When there are the heating samples placed in the chamber, please employ the additional power supply instead of this machine power supply as the control power supply of the samples.

Due to a dangerous current produced in running process of the test chamber, therefore, non-professional personnel do not open the cover plate of the electrical control box.

If the test chamber is not equipped with the humidifying function, please pay attention to the different operation steps and requirements when reading the instructions.

During running, all kinds of motors and fans are under the control of the controller and activated according to the orders. Therefore, don't touch any component in the temporarily idle state so to prevent the component from starting up suddenly, which may cause personal injury.

When you do need to work near the rotating parts, please cut off the main power switch and ensure the protective equipment in good condition.

Do not move the test chamber when there is a sample in it, otherwise, the sample may reverse or fall off.

The test chamber must be installed horizontally; otherwise, it will cause alarm or unstable humidity control.

Before use, make sure that the test chamber is fixed, namely the caster is unearthed and adjustable feet are grounded, otherwise, the test chamber may move by accident under the effect of external force.

Please carefully read the safety requirements and safety signs on the equipment before testing with the test chamber.

For more details, please feel free to contact sales@lenpure.com

Please visit www.lenpure.com