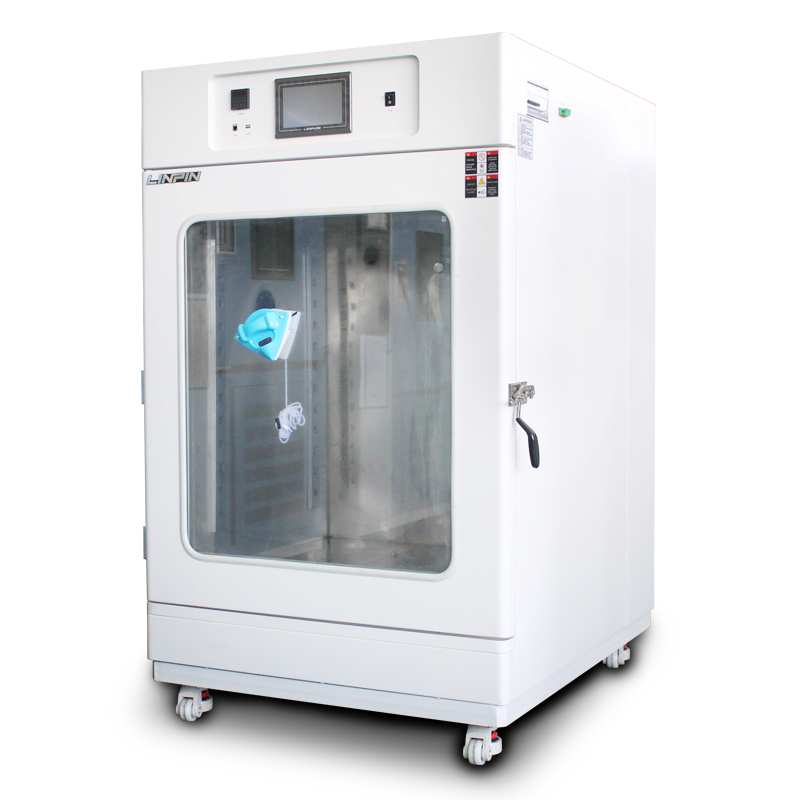

Water Condensation Climate Chambers for DIN 50018

Lenpure Programmable Water Condensation Test Chamber give the maximum durability and performance for your most demanding test requirements.It is the necessary test equipment for aviation, Aerospace, automotive, electronics, military and solar panel industry etc.It can be used to test and determine the parameters and performance of electrical, electronic products and materials in the most extreme temperature and humidity conditions.

Feature

●Programmable Touch Screen Controller

●Custom Sizes Available

●Running Time Meter

●Wide Temperature and Humidity Ranges

●Capable of Handling Extreme Temperature and Humidity

●High Performance Even Under Load

●Incandescent Interior Lighting

●Modular,Robust Reliable Construction

●Stainless Steel Interior

●Painted Galvanized Steel Exterior For Long Life

●Heavy-duty Flooring to Support Vehicles

●Mechanical Cooling

●Comprehensive Safety Features

●Refrigeration Gauges

●Refrigeration Sound Deadening Package

●Low or Zero Ozone Depletion Refrigerants

●All Circuits Fused or Circuit Breaker Protected.

●All Wiring Numbered or Color Coded

●Compressor Overload Protection

●Prefabricated for On-Site Installation

| Sizes of Water Condensation Test Chambers | |||||

| Model | Volume (L) | Performance | Rated Power | Internal Dimension (mm) D*W*H | External Dimension (mm) D*W*H |

| LRHS-101-LN | 101 |

Temperature Range(°C) 25°C~45°C Humidity Range (R.H) 100%RH or customized |

2.5kW | 450*450*500 | 650*950*1500 |

| LRHS-225-LN | 225 | 3.0kW | 500*600*750 | 700*1100*1550 | |

| LRHS-504-LN | 504 | 3.8kW | 700*800*900 | 900*1300*1600 | |

| LRHS-800-LN | 800 | 5.0kW | 800*1000*1000 | 1000*1500*1700 | |

| LRHS-1000-LN | 1000 | 5.0kW | 1000*1000*1000 | 1200*1500*1700 | |

|

Note: In the Model, the number means volume of test chamber's working room. For example, model LRHS-101-LN means the volume of this test chamber is 101L. LRHS-225-LN means the volume is 225L |

|||||

| Basic Specification | |||||

| Performance | Temperature Range | 25°C~45°C | |||

| Temperature Fluctuation | ±0.5°C | ||||

| Temperature Uniformity | ±2.0°C | ||||

| Ramp Rate | RT~40°C≤90min | ||||

| Humidity Range | 100% R.H | ||||

| Humidity Fluctuation | ﹢2% -3% R.H | ||||

| Material | External Casing | Cold-rolled A3 (Q235) steel plates with plastics painted. | |||

| Interior Working Room | Stainless Steel Plates SUS304 with miror surface | ||||

| Heat Isolation | Polyurethane foams and fine glass fibres | ||||

| Illumination Lamp | Philips® one in per standard test chamber. | ||||

| Casters | 4pcs, with PU covered for protection. Height adjustable and direction universal. | ||||

| Viewing Window | Multi-layer hollow toughened glass with conductive films for heating to defrost | ||||

| Door | Manually operated sliding door with unlock button | ||||

| Heating & Cooling System | Heater | Steipped Nickel-chromium Wire Heater | |||

| Air Blower | Anti-temperature stainless fan blades with low noise | ||||

| Control System | Controller |

7" Programmable colorful touch-screen display LCD English Display Microcomputer integrated controller |

|||

| Functions | Data Record (Max 600 days x 24hrs), History Curve, USB data download & upload, Remote controlling through PC, Automatic protection alarms, etc. | ||||

| Program | 1~1000 programs, 1~999 steps for per program, Max 99hrs 59mins for per program. 10 programs can be interlinked. | ||||

| Temperature Sensor | Platinum Resistance.PT100Ω | ||||

| Running Model | Constant/Fix-value Model and Programmable Model | ||||

| I/O Interface | Communicate port (RS485) to connect test chamber to a PC | ||||

| Standard Configuration | Test Chamber x 1, Specimen Holder Shelf x 2, φ100mm Cable Access Port x 1 with 1 soft plug, EMO x 1, Tri-color Indicator x 1, etc. | ||||

| Safety Protection | Power leakage protection/Compressor over-heat, over-load or over-current protection/Dry burning protection. | ||||

| Voltage | AC220V/380V/440V±10%, 50Hz/60Hz or as per requirement | ||||

| Ambient Enviromental for application | 23±5°C ≤ 75%R.H | ||||

| Test Standards (not limited to) |

DIN EN ISO 6270-2 DIN50018 |

||||

The condensate water testing machine can measure the corrosion resistance of the tested material in the corresponding natural environment in a short time through the simulation and strengthening of the natural environment, thereby providing the data and the basis for screening the product or the formula for the user.

The experiment box can be used as a 100% humidity test, and can also be used for testing low-temperature, high-temperature and humidity-integrated test, and is an essential test equipment for the quality inspection institute, the electronic-electric and steam-coal industry and so on.

In general, the bottom of the condensate tank shall be provided with a water tank to accommodate the amount of water specified in the standard DIN50018.

The temperature in the water condensation test chamber will be adjusted by heating the water in the tank, and if the amount of heat transferred through the water in the tank is not enough, the air in the test box can be supplemented and heated to raise the air temperature of the test chamber to a sufficient level.

The conditions that must be observed in the condensate test box under the constant condensation climate or condensation-alternating climate load in order to make the results measured in different laboratories comparable. The condensate water test box is mainly used to determine the characteristics of the test in wet environment and the defects of corrosion protection, the test should not produce additional heat during the load process, and the test duration of the sample switch test preparation test, The calculation and evaluation of test results should refer to the corresponding standards.

Due to the radiation effect of the wall of the condensate water chamber or the cooling effect of the test itself, the temperature of the test surface in the test box is lower than the saturation temperature of the ambient air in the test box, The air temperature in the test box is 40 degrees.

The condensate test chamber shall not be used to test the following substances or products containing them:

l Gasoline, acetaldehyde, propylene oxide, carbon disulfide and other substances less than-30 ℃.

l Common ethane, ethylene oxide, acetone, benzene, methyl ethyl ketone and other substances with ignition point above-30 ℃ but less than 0 ℃.

l Methanol, ethanol, dicarboxylic acid amyl ester and other substances whose ignition point is above 0 ℃ and below 30 ℃.

l Kerosene, light oil, turpentine, isoamyl alcohol, sour vinegar and other substances with ignition points above 30 ℃ and below 65 ℃.

l 5. Flammable gases: hydrogen, acetylene, ethylene, methane, ethane, propane, butane and others at atmospheric pressure at 15 ℃ A gas that can be burned.

How to do the test, the steps are as follows:

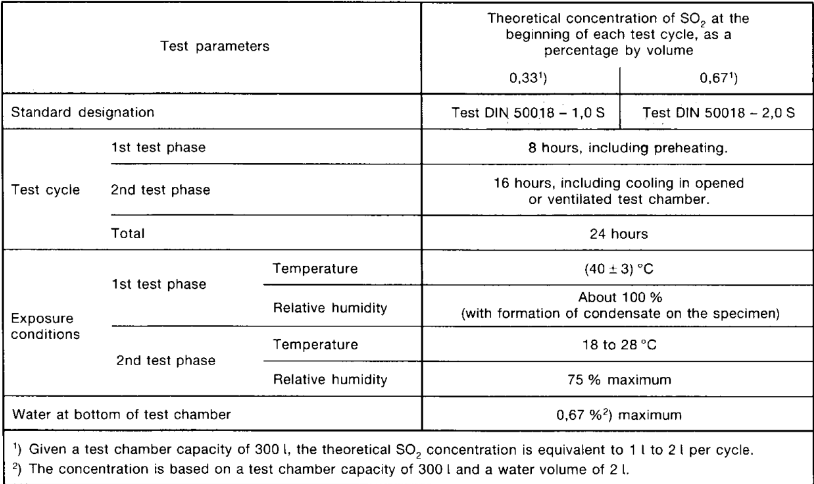

1. At the beginning of the first experimental phase of each cycle, the studio temperature is achieved to 31 ℃ within an hour. At the same time, the humidity of the sample should be kept at the whole first test stage.

Make sure that sulfur dioxide has been dissolved in the water of the test room in the first stage.

2. In the second stage, stop heating, turn on the ventilation in the studio, and then press the following table to carry out the test.

For more details, please feel free to contact sales@lenpure.com

Please visit www.lenpure.com