Din50 017 is the general conditions which have to be observed in respect of the stressing of specimens in conditions water constant atmosphere or in condensations water alternating atmospheres. In order to ensure that the result of test carried out indifferent laboratories are reproducible.

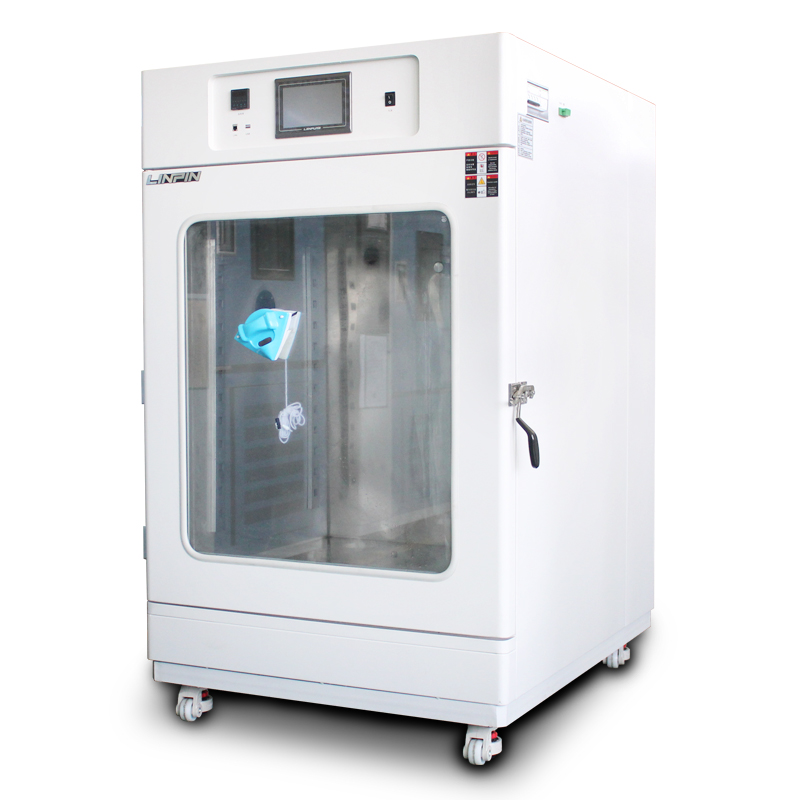

Below is the introduction about Lenpure water condensation test chamber.

Feature

●Programmable Touch Screen Controller

●Custom Sizes Available

●Running Time Meter

●Wide Temperature and Humidity Ranges

●Capable of Handling Extreme Temperature and Humidity

●High Performance Even Under Load

●Incandescent Interior Lighting

●Modular,Robust Reliable Construction

●Stainless Steel Interior

●Painted Galvanized Steel Exterior For Long Life

●Heavy-duty Flooring to Support Vehicles

●Mechanical Cooling

●Comprehensive Safety Features

●Refrigeration Gauges

●Refrigeration Sound Deadening Package

●Low or Zero Ozone Depletion Refrigerants

●All Circuits Fused or Circuit Breaker Protected.

●All Wiring Numbered or Color Coded

●Compressor Overload Protection

●Prefabricated for On-Site Installation

Condensation water test atmosphere promote the condensations of atmosphere humidity on the surfaces of specimens, the temperature of which are lower than the temperature of the saturated air in the test room , due to radiations onto to the chamber walls or to the cooling of the specimen.

The atmosphere temperature in the test room during the condensation process of the condensation water test atmosphere process of standard shall be 40 ℃。

The quantity of the condensations water formed on the surface of the specimen may also exercise an important influence on the action of the condensation water; this quantity will be affected by the ambient temperature in the installation room or by the cooling of the specimen.

A vapour-tight climatic chamber is essential for testing in a warm and humid atmosphere. The material of the inner walls must be corrosion-resistant and must not affect the specimens. The climatic chamber shall be usually equipped with a floor through which act the receptacle for the quantity of water. The test room shall be tempered by heating the floor water.

Here is the specification for your reference when you choose the water condensation test chamber.

| Basic Specification | ||

| Performance | Temperature Range | 25°C~45°C |

| Temperature Fluctuation | ±0.5°C | |

| Temperature Uniformity | ±2.0°C | |

| Ramp Rate | RT~40°C≤90min | |

| Humidity Range | 100% R.H | |

| Humidity Fluctuation | ﹢2% -3% R.H | |

| Material | External Casing | Cold-rolled A3 (Q235) steel plates with plastics painted. |

| Interior Working Room | Stainless Steel Plates SUS304 with miror surface | |

| Heat Isolation | Polyurethane foams and fine glass fibres | |

| Illumination Lamp | Philips one in per standard test chamber. | |

| Casters | 4pcs, with PU covered for protection. Height adjustable and direction universal. | |

| Viewing Window | Multi-layer hollow toughened glass with conductive films for heating to defrost | |

| Door | Manually operated sliding door with unlock button | |

| Heating & Cooling System | Heater | Steipped Nickel-chromium Wire Heater |

| Air Blower | Anti-temperature stainless fan blades with low noise | |

| Control System | Controller |

7" Programmable colorful touch-screen display LCD English Display Microcomputer integrated controller |

| Functions | Data Record (Max 600 days x 24hrs), History Curve, USB data download & upload, Remote controlling through PC, Automatic protection alarms, etc. | |

| Program | 1~1000 programs, 1~999 steps for per program, Max 99hrs 59mins for per program. 10 programs can be interlinked. | |

| Temperature Sensor | Platinum Resistance.PT100Ω | |

| Running Model | Constant/Fix-value Model and Programmable Model | |

| I/O Interface | Communicate port (RS485) to connect test chamber to a PC | |

| Standard Configuration | Test Chamber x 1, Specimen Holder Shelf x 2, φ100mm Cable Access Port x 1 with 1 soft plug, EMO x 1, Tri-color Indicator x 1, etc. | |

| Safety Protection | Power leakage protection/Compressor over-heat, over-load or over-current protection/Dry burning protection. | |

| Voltage | AC220V/380V/440V±10%, 50Hz/60Hz or as per requirement | |

| Ambient Enviromental for application | 23±5°C ≤ 75%R.H | |

If the quantity of heat introduced via the water is insufficient to heat up the air in the test room to the required temperature, then this air can be heated up additionally.

The dimensions of the climatic chamber and the arrangement of its temperature measuring and control equipment are optional.

The climatic chamber shall be provided with a suitable door or other aperture of being closed, which allows the test room to be or other aperture capable of being closed, which allows the test room to be charged with specimens and to be ventilated.

Climatic testing devices not equiped with water-filed floor through must be fitted out insuch a way that an adequate formation of condensation water on the specimens is achieved in them.

The climatic chamber shall be installed in a room with an ambient atmosphere not containing any corrosive constituents.

For more details, please fell free to contact sale@lenpure.com

Or visit www.lenpure.com