In order to obtain good correlation of results between laboratories, it is necessary to observe the recommended operating conditions and to ensure the correct spacing of panels and suitable siting of the apparatus. If these conditions are observed, good correlation of results between laboratories may be obtained for periods of exposure up to 240 hours but for periods longer than this, there may be some divergence for results.

The method of test described below requires to be completed, for any particular application, by the following supplementary information. This information is to be derived from the British Standard or other specification for the material under test or, where appropriate, is to be the subject of agreement between the purchaser and the vendor.

1. Nature of substrate and method of preparation.

2. Method of application of test coating to substrate

3. Thickness or weight, or both, of coating and whether it is a single film or a multicoat system.

4. Duration and the conditions of drying of coated panel (or conditions of storing if applicable) before testing.

5. Duration of test.

6. How inspection of the test coating is to be made and what characteristics are to be considered in evaluating its resistance properties.

Unless otherwise stated use a panel approximately 150mm 100mm of burnished steel, 1.25mm (18B.G) thick, prepared in accordance with the method described in BS 3900-A3*.

Coat the panel with the material under test by the appropriate method and dry for the specified time in the specified manner, if normal drying conditions are specified, these should be interpreted as a temperature of 20±2 ℃ and a relative humidity of 60-70% with free circulation of air and not exposed to direct sunlight. Coat the back and edges of the panel with a good protective paint.

The apparatus described below has been found to give consistent results and should be used for reference purpose. Other designs of apparatus used under controlled conditions have been found to give results which correlate with the standard apparatus and may be used, subject to agreement between the parties.

The standard apparatus shall be operated so that the following conditions are observed:

1. Salt spray. The salt spray shall be prevented by the baffle from impinging directly on the test faces of the panels.

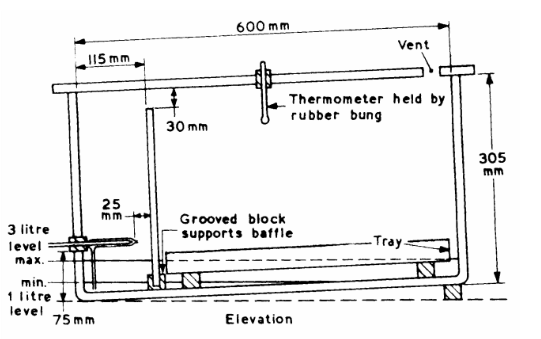

2. Solution level. The salt solution in the tank is maintained between the maximum (3 litre) and minimum (1 litres) levels indicated in Figure 1.

3. Spray collection. The salt solution drained from the test panels is collected in the tray and is emptied at regular intervals to prevent recirculation or contact with the panels.

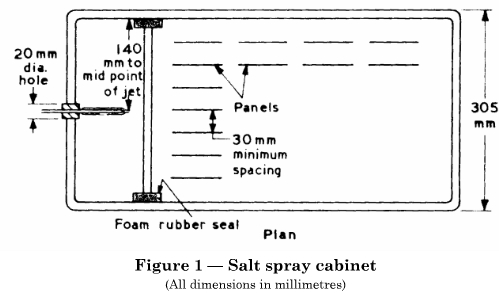

4. Supporting and spacing of panels. The test panels are positioned on non-metallic supports, not less than 30mm apart and in the case of the outermost panels so as to ensure that they do not touch the side of the tank. The short edges of the panels are parallel to the longer dimensions of the tank with the test faces uppermost at about 15 to the vertical.

5. Air pressure. The air pressure to the spray jet is maintained at 70±7kPa. (10±1 lbf/in²).

6. Sitting of apparatus. The apparatus is sited in diffuse light, away from radiators and draughts and is operated at a temperature of 20±2℃ unless otherwise specified.

7. Cleaning the apparatus. The apparatus, including the spray jet, is cleaned periodically, at least at weekly intervals, to remove the accumulated salt deposit and is then refilled with fresh salt solution.

The reagents used shall be of a recognized analytical quality. Distilled water or water otherwise produced of equal purity shall be used. The composition of the test solution shall be as given below:

Sodium chloride as NaCl 26.5g

Magnesium chloride as MgCl2 2.4g

Magnesium sulphate as MgSO4 3.3g

Potassium sulphate as KCl 0.73g

Sodium hydrogen carbonate as NaHCO3 0.20g

Sodium bromide as NaBr 0.28g

Calcium chloride as CaCl2 (to be added last) 1.1g

Water to 1000ml

Expose the panel in the apparatus for the specified period.

Remove the panel, wash it in running water and blot quickly with absorbent paper.

Examine the film immediately for blistering, softening and other signs of deterioration. Then immediately remove a 150mm×50mm strip from the test face with a non-corrosive paint remover. Examine the exposed metal for signs of corrosion. To preserve the panel for reference purposes, the exposed area should be protected by suitable transparent lacquer.

The test report shall contain at least the following information:

1. Identification of material under test.

2. The British Standard, product specification or other document setting out the supplementary information required for the test.

3. Any deviation from the standard test procedure whether by agreement or otherwise, such as scratching through the film before exposure of panel, test temperature if other than 20℃ etc.

4. The results of the test in terms of the stated requirements.

Glass tank with based and walls approximately 5mm thick, fitted with a plate glass cover with a 20mm diameter central hole for a thermometer and a 25mm diameter vent, 17.5mm from the inside wall at one end of the tank. The tank is raised at one end and the baffle and the tray are supported on blocks, all the blocks used being of 25mm square section.

For more details, please feel free to contact sales@lenpure.com

Please visit www.lenpure.com