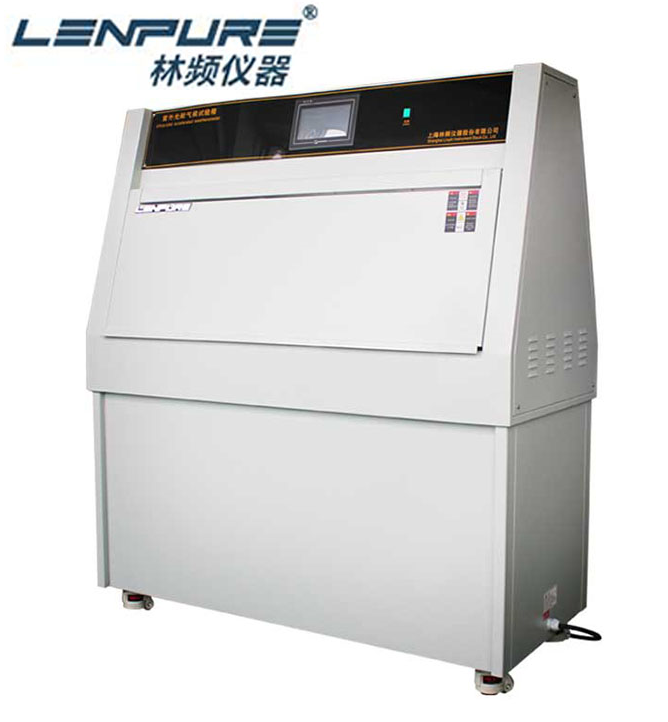

Environmental Test Chambers for ASTM D750 Standard Practice for Rubber Deterioration Using Artificial Weathering Apparatus

This practice covers specific variations in the test conditions and procedures that shall be applicable when Practice G151 plus either Practice G152, G153, G154, or G155 are employed for exposure of vulcanized rubber compounds. It also covers the preparation of test specimens and the evaluation of results.

The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Apparatus

Historically, this standard utilized carbon arc exposure apparatus in a test method for rubber deterioration. The options of using either xenon arc or fluorescent UV exposure apparatus have been added in order to update the tests with the use of light sources that give a better representation of the effects of solar radiation than carbon arcs.

The xenon arc source with daylight filters. which conforms to Practice G155, gives the closest simulation of the full spectrum of terrestrial solar radiation, and the fluorescent UV/condensation test apparatus with the UVA-340 fluorescent UV lamp, which conforms to Practice G154. closely simulates the UV of terrestrial solar radiation in the 300 to 360 nm region.

The type of carbon-arc exposure apparatus preferred is the filtered open flame carbon arc, which conforms with Practice G152. but the enclosed carbon arc apparatus conforming with Practice G153 may be used by mutual consent of the concerned parties.

Test Specimens

Unless otherwise mutually agreed upon, test specimens prepared especially for this test or cut from the material to be evaluated shall be three tension test replicates prepared in accordance with Practices D3182 and D3183.

An additional three tension test replicates shall be prepared and stored for testing in accordance with 7.1.3. Unless otherwise mutually agreed upon, the specimens should have a maximum thickness: of 0.75 mm (0.030 in.) and a minimum thickness 0.60 mm(0.025 in.).

If evaluation is limited only to visual observation, then specimens of any thickness may be used and the thickness shall be included in the report. Dimensions of the specimens are no critical but previous practice called for specimens 75 mm (3 in.) wide by 150 mm (6 in.) in length.

Exposing at least duplicate sets, preferably triplicate sets, of test specimens whenever possible is recommended.

Specimens cut from rubber products may be buffed.

Procedure

Firmly fasten the test specimens in a jig or holder that permits exposure either with or without elongation. While exposures are usually made without elongation of the test specimen, when mutually agreed upon, any specified amount of elongation may be employed but this must be reported in the results of the test.

The four exposure procedures use different types of exposure sources and test conditions. Therefore, they may produce different test results. They shall not be used inter changeably without supporting data that demonstrates equivalency of the procedures for the materials tested. Choice of the type of apparatus and duration of exposure shall be by mutual agreement among the interested parties.

For the allowed operational fluctuations of the specified set points for irradiance, temperature, and relative humidity, refer to Table A3.1 in Practice G151. If the actual operating conditions do not comply with the maximum allowable fluctuations in Table A3.1 after the equipment has stabilized, discontinue the test and correct the cause of the problem before.

Specimens should be confined to an exposure area in which the irradiance is at least 90% of the irradiance at the center of the exposure area. Unless it is known that irradiance uniformity meets this requirement, use one of the procedures described in Practice G151.

Appendix X2 to ensure equal radiant exposure on all specimens or to compensate for differences within the exposure chamber. If the specimens do not completely fill the racks, fill the empty spaces with blank metal panels to maintain the test conditions within the chamber.

The apparatus shall be operated continuously. However if the test needs to be interrupted to perform routine maintenance or inspection, it should be during a dry period.

Procedure for Exposure in Open Flame Carbon Arc Apparatus (Practice G152) or Enclosed Carbon Arc Apparatus (Practice G153)-Unless otherwise specified, use the following operating conditions.

The open flame carbon arc apparatus and the enclosed carbon arc apparatus shall be used with daylight type filters and conform with the spectral power distribution specifications in Practices G152 and G153. respectively.

Unless otherwise mutually agreed upon or specified, operate with a cycle cam of 102 min light followed by 18 min of light plus water spray on the front surface of the sample (see Note 1). The water spray temperature is typically 21 ± 5℃.but may be lower if ambient water temperature is low and a holding tank is not used to store purified water.

NOTE 1: This cycle is recommended only because it has long historical usage, not because it has been established for technical reasons as superior.

Set the uninsulated black panel temperature (BPT) at 63°C during the dry period of exposure to light.

Set the relative humidity at 60 % during the dry period of exposure to light.

Procedure for Exposure in Xenon Arc Light Apparatus (Practice G155), unless otherwise specified, use the following operating conditions:

The default exposure cycle shall be 102 min light only followed by 18 min light plus either water spray on the front surface or immersion in water.

Set the uninsulated black panel temperature (BPT) at 63C during the dry period of exposure to light. For the equivalent insulated black panel temperature [black standard temperature (BST), consult the manufacturer of the apparatus.

Relative humidity shall be set at 60 % during the dry period of exposure to light in xenon arc apparatus that provides for control of relative humidity.

The chamber air temperature shall be set at 44C in equipment that provides for adjustment of the chamber air temperature.

Procedure for Exposure in Fluorescent UV Condensation Apparatus (Practice G154) Unless otherwise specified, use the following operating conditions:

Use fluorescent UVA-340 lamps that comply with the spectral power distribution specifications in Practice G154.

The irradiance level shall be set at 0.77 W/(m2/nm) at 340 nm in apparatus with irradiance control.

The exposure cycle shall be 8 h UV at an uninsulated black panel temperature of 60C followed by a dark period of 4 h with wetting by condensation at an uninsulated black panel temperature of 50C.

The periods of exposure shall be a mutually agreed upon "specified time or amount of radiant energy. It shall be determined by one of the following procedures (for guidance on minimum exposure, consult Section 8 of Practice G151):

A mutually agreed upon specified number of hours.

The number of hours of exposure required to produce mutually agreed upon minimum detectable changes in either the test specimen or an agreed upon standard sample.

If you are still interested in any kind of environmental test chambers, and I'm pleased provide some of our details and project to you. That's more, at present we have more attractive price for you. Welcome for inquiry any time, I will reply asap!

If you want to know more information about climate chambers or our company, please feel free to contact sales@lenpure.com or visit http://www.lenpure.com/ .