Environmental Test Chambers for JISZ 2371 Methods of salt spray testing

In the past, we wrote a lot of articles about programmable temperature and humidity test chamber. Today we gonna talk about another environmental test chamber --- salt spray test chamber. This Japanese Industrial Standard has been prepared based on the third edition of ISO 9227 published in 2012 with some modifications of the technical contents.

This standard specifics the salt solutions, the apparatus, and the procedure( including evaluation of cabinet reproducibility related to corrosivity, test specimens, test conditions, and evaluation of test results) to be used in conducting the neutral salt spray test, acetic acid salt spray test and copper-accelerated acetic acid salt spray ( CASS) tests for assessment of the corrosion resistance of metallic materials, with or without electroplating, or inorganic film or organic coating such as painted coat.

Preparation of salt solution for testing shall be as follows:

1. Salt used for salt solution for testing shall be sodium chloride of special grade specified in JIS K 8150, or any sodium chloride at least equivalent thereto.

Any sodium chloride at least equivalent thereto as referred to above shall contain less than 0.001% mass fraction of copper and less than 0.001% mass fraction of nickel, as determined by atomic absorption spectrophotometry or another analytical method of similar sensitivity. Further, it shall not contain more than 0.1% mass fraction of sodium iodide, or more than 0.5% mass fraction of total impurities calculated for dry salt. It shall not contain anticaking agent, which may accelerate or inhibit the corrosion.

2. Water used shall be deionized or distilled water with a conductivity not higher than 20μS/cm at 25℃±2℃. The conductivity should preferably be 1μS/cm or lower.

3. In a vessel of an inert material such as resin, dissolve a sufficient mass of salt to produce a concentration of 50g/l±5g/l. After thorough agitation, the specific gravity range of the collected salt solution shall be 1.029 to 1.036 when measured by means of a density meter. The salt solution concentration may be confirmed by means of another electric measuring device such as a salt concentration meter. If the obtained solution is found to be outside the specified range, prepare a new solution.

PH adjustment of salt solution for testing

1. NSS test

Adjust the PH of the salt solution so that the PH of the sprayed salt solution collected within the spray cabinet is 6.5 to 7.2 at 25℃±2℃.

2. AASS test

Check that the PH of samples of the sprayed solution collected in the test cabinet at 25℃±2℃ is between 3.1 and 3.3.

3. CASS test

Check that the PH of samples of the sprayed solution collected in the test cabinet at 25℃±2℃ is between 3.1 and 3.3.

The apparatus used for this test shall be composed of a spray cabinet provided with mist dispersion tower or atomizer nozzle, salt solution reservoir, test specimen supports, fog collectors, and salt solution tank, air compressor, air saturator, temperature controls, exhaust duct, etc, and shall be as follows.

1) The apparatus used for this test shall be maintained and controlled so that the test can be performed normally.

2) The exhaust duct shall not be influenced by the wind pressure of the open air.

3) Preference shall be given to apparatus that has a means for properly dealing with sprayed solution after the test, prior to releasing it from the building for environmental conservation, and for drawing water prior to discharging it to the drainage system.

The salt spray cabinet shall be as follows:

1) The cabinet shall be such that the distribution of the sprayed solution and the temperature can be controlled to be homogeneous, and its form and size may be l optional. Where the cabinet volume is less than 0.4m3, sufficient attention shall be paid to the distribution of the spray and temperature.

2) The mist dispersion tower and the atomizer nozzle shall be made of insert material such as plastics, and shall be capable of spraying the solution uniformly over the test specimens from upper part of the spray cabinet.

3) The spraying shall be performed by free circulation of sprayed solution, and the direction of the mist dispersion tower or the atomizer nozzle shall be adjusted so that the sprayed solution does not directly fall on the test specimen. The mist dispersion tower is suitable for this purpose. The upper parts of the cabinet shall be designed so that drops of the sprayed solution formed on its surface do not fall on the specimens being tested.

4) The sprayed solution and temperature inside the spray cabinet shall not be affected by the open air.

5) The test specimen supports shall be capable of holding the test specimens at the specified angle.

The temperature near the test specimen supports inside the spray cabinet shall be maintained at 35℃±2℃ for NSS and AASS tests and 50℃±2℃ for CASS test. The temperature shall be measured at least 100mm from the walls.

The spraying device shall be as follows.

a. The compressed air supplied to the mist dispersion tower or atomizer nozzle for spraying the salt solution shall be passed through a filter to remove all traces of oil or solid matter, and the atomizing pressure shall be at an overpressure of 70kPa to 170kPa. The pressure should be 98kPa±10kPa.

b. In order to prevent the evaporation of water from the sprayed droplets, the compressed air shall be humidified before entering the mist dispersion tower or atomizer nozzle by passing through a humidifier or an air saturator.

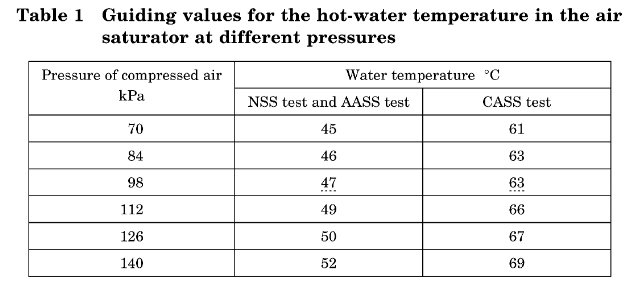

The compressed air supplied to the mist dispersion tower or atomizer nozzle shall be heated so that it does not cause the temperature inside the spray cabinet to fluctuate severely when mixed with the salt solution. An air saturator should be used to control the humidity and temperature of the compressed air. Table 1 shows the guiding values that are given for the hot-water temperature in the air saturator at different pressures.

c. The water used for the humidifier or the air saturator for humidifying the compressed air supplied to the mist dispersion tower or atomizer nozzle shall be not higher than 20 μS/cm at 25℃±2℃.

d. The salt solution to be supplied to the mist dispersion tower or the atomizer nozzle shall be maintained to be continuous and uniform spray mist. For a stable spraying, the level of the salt solution in the salt solution reservoir, or flow of the salt solution supplied to the mist dispersion tower or atomizer nozzle shall be controlled.