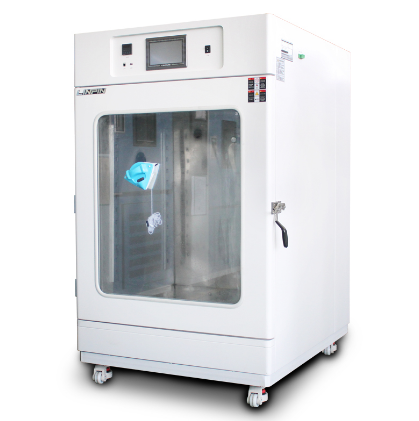

Environmental Test Chamber for ISO 6270-2 (CH): Paints and varnishes -Determination of resistance to humidity-Part 2: Condensation (in-cabinet exposure with heated water reservoir)

Shanghai Lenpure Programmable Water Condensation Environmental Test Chambers can give the maximum durability and performance for your most demanding test requirements.It is the necessary test equipment for aviation, Aerospace, automotive, electronics, military and solar panel industry etc.It can be used to test and determine the parameters and performance of electrical, electronic products and materials in the most extreme temperature and humidity conditions.

●Programmable Touch Screen Controller

●Custom Sizes Available

●Running Time Meter

●Wide Temperature and Humidity Ranges

●Capable of Handling Extreme Temperature and Humidity

●High Performance Even Under Load

●Incandescent Interior Lighting

●Modular,Robust Reliable Construction

●Stainless Steel Interior

●Painted Galvanized Steel Exterior For Long Life

●Heavy-duty Flooring to Support Vehicles

●Mechanical Cooling

●Comprehensive Safety Features

●Refrigeration Gauges

●Refrigeration Sound Deadening Package

●Low or Zero Ozone Depletion Refrigerants

●All Circuits Fused or Circuit Breaker Protected

●All Wiring Numbered or Color Coded

●Compressor Overload Protection

●Prefabricated for On-Site Installation

Test standards of Lenpure Programmable Water Condensation Environmental Test Chambers

This test equipment conforms to following test standards (but not limited to):

●DIN EN ISO 6270-2 (CH, AT, AHT)

●DIN50018

●BS 3900 F2

●BS 3900 F15

●DIN 50018-97

This document specifies the general conditions and procedures which need to be observed when testing coated test specimens in constant condensation-water atmospheres or in alternating condensation water atmospheres, in order to ensure that the results of tests carried out in different laboratories are reproducible.

The description of designation in the ISO 6270-2 (CH): Paints and varnishes -Determination of resistance to humidity-Part 2: Condensation (in-cabinet exposure with heated water reservoir):

The condensation-water test atmospheres are designated as follows:

Test atmosphere:

CH: Condensation atmosphere with constant humidity;

AHT: Condensation atmosphere with alternating humidity and air temperature;

AT: Condensation atmosphere with alternating air temperature.

The requirements of test atmospheres in the ISO 6270-2 (CH): Paints and varnishes -Determination of resistance to humidity-Part 2: Condensation (in-cabinet exposure with heated water reservoir):

Condensation-water test atmospheres promote the condensation of atmospheric humidity on the surfaces of test specimens, the temperatures of which are lower than the temperature of the saturated air in the climatic chamber, due to radiation onto the chamber walls or to the cooling of the test specimen.

The atmospheric temperature in the climatic chamber during the condensation process described in this document is (40 ±3) C.

The condensation-water test atmosphere may be either a constant-humidity (CH) or an alternating (AHT, AT) atmosphere. If, in addition to the action of the condensation water, the change in atmospheric temperature and the change in atmospheric humidity have an important effect on the test specimens, an alternating atmosphere should be chosen.

The quantity of condensation water formed on the surface of the coating may also exercise an important influence on the action of the water; this quantity will be affected by the ambient temperature in the installation room or by the cooling of the test specimen.

The condensate which drips off the test specimens consists of condensation water and also, in some instances, of solid and liquid constituents of the coating dissolved in the condensation water or mixed with it.

Reproducible results can only be expected if the test procedure and test conditions remain constant for series of tests.

In the case of alternating atmospheres, a cycle time of 24 h shall be used as a general rule. A shorter cycle time (12 h or 16 h) and a correspondingly shortened time for the two test periods may be used for the AT test atmosphere.

The requirements of climate chambers in the ISO 6270-2 (CH): Paints and varnishes -Determination of resistance to humidity-Part 2: Condensation (in-cabinet exposure with heated water reservoir):

A vapour-tight climatic chamber is essential for testing in a warm and humid atmosphere. The material of the inner walls shall be corrosion-resistant and shall not affect the test specimens. The climatic chamber is usually equipped with a floor trough which acts as the receptacle for the quantity of water prescribed in 9.1. The climatic chamber shall be controlled by heating the water in the floor trough.

If the quantity of heat introduced via the water is insufficient to raise the air temperature in the climatic chamber to the required level, then additional heating can be employed.

The heating-up time will depend on the nature and quantity of the test specimens, and also on the ratio of the surface of the water in the floor trough to the surface of the walls of the climatic chamber, and on the water temperature. The water temperature should preferably not exceed 60C in order to prevent excessive vapour formation.

The dimensions of the environmental test chambers and the arrangement of its temperature-measuring and control equipment are optional, provided that the test conditions in accordance with Clause 8 and 9.3 are observed and that the temperature is measured.The climatic chamber shall be provided with a suitable door or other aperture capable of being closed, which allows the climatic chamber to be charged with test specimens and to be ventilated.

The requirements of test specimens in the ISO 6270-2 (CH): Paints and varnishes -Determination of resistance to humidity-Part 2: Condensation (in-cabinet exposure with heated water reservoir):

The test specimens shall be arranged in the chamber at any angle greater than or equal to 60° to the horizontal in such a way that they are not in close contact with each other and that they are able adequately to radiate heat.

The following minimum spacing shall be observed:

Distance from the wall: snot less than 100 mm

Distance of the bottom edge of the test specimen from: not less than 200 mm

Spacing between adjoining test specimens: not less than 20 mm

Precautions shall be taken to ensure that no condensation water is allowed to drip onto the test specimens from the walls or ceiling of the climatic chamber, nor from other test specimens. Make sure that condensation forms on all test specimens.

If you are still interested in any kind of environmental test chambers, and I'm pleased provide some of our details and project to you. That's more, at present we have more attractive price for you. Welcome for inquiry any time, I will reply asap!

If you want to know more information about climate chambers or our company, please feel free to contact sales@lenpure.com or visit http://www.lenpure.com/ .