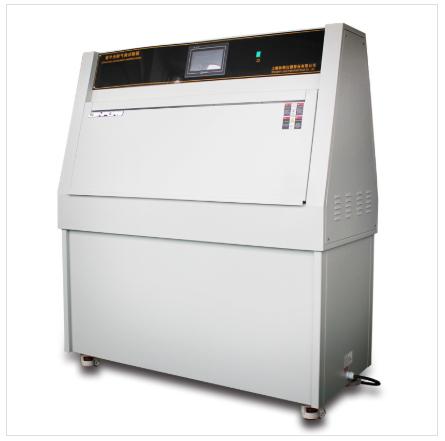

Climate Chambers for DIN EN 1297 UV weathering aging chamber

Lenpure UV-Lamp Weathering Environmental Test Chambers take fluorescent UV lamp as light source to simulate the UV irradiation in natural light and condensation to conduct accelerated weathering test to the materials. It can simulate the UV, rain, high temperature, high humidity, condensate, darkness and other environmental conditions in natural climate and combine them in a circle, and carry out these circles automatically.

▪Black Panel Temperature (BPT) Control

▪Touch-screen controller, user-friendly

▪With irradiance monitor function

▪Import Q-Lab air-cooled UV lamp, more economical, more efficient and easier to maintain. Lamp life of 1800 hours.

▪Door Safety and Over-temperature Shutoff

▪The irradiance control system continuously monitors and controls the output of the light, which ensures accurate exposure and repeatable test results.

▪Allows the user to simultaneously control and monitor relative humidity, blackboard temperature and air temperature in the box.

▪All circuits fused or circuit breaker protected, overload protection.

▪CE Compliance and UL & CSA Certified

▪ Tri-color Indicator and EMO (Emergency-off Switch) available.

Test Standards

ASTM D4329 , ASTM G151

ISO 4892-1/3 , ISO 11507 , ISO 11895

EN 927-6 , EN 12224

SAE J2020

JIS D 0205

This test equipment comply with above test standards (but not limited to).

DIN EN 1297 specifies the method for exposure of factory made bitumen or plastic or rubber sheets for root waterproofing to combined effects of long term exposure by UV radiation, elevated temperature and water as means of artificial ageing.

Fluorescent UV lamp

lamp in which primary radiation from a low pressure mercury arc is transformed into higher wavelength UV by means of a fluorescent phosphor. The spectral emission of a fluorescent lamp is determined by the spectral emission of the fluorescent phosphor and the transmission characteristics of the glass tube. A fluorescent UV lamp is a lamp in which the radiant emission in the ultraviolet region of the spectrum < 400 nm makes up at least 80 % of the total radiation output.

Irradiance

Incident radiant flux onto a surface per unit area.

Spectral irradiance

Radiant flux per unit area per wavelength interval.

UV-radiation

Radiation with a wavelength A between: 100 nm <A<400 nm.

Exposed side

Side of the test specimen designated by the manufacturer to be exposed to the sunlight.

Principle

Test specimens cut from the product sample are exposed in an apparatus with fluorescent UV lamps at specified irradiance, black standard temperature (BST), relative humidity and cyclic water spraying.

The resistance to this exposure is determined by follow-up tests described in the product standards on flexible bitumen or plastic or rubber sheets for roof waterproofing.

Apparatus

Laboratory light source

The UV source shall be an array of fluorescent UV lamps of type I (340 nm) or a fluorescent UV lamp combination in accordance with EN ISO 4892-3 with a mean UV irradiance in the plane of the specimen surfaces of (45 ± 5) W/m2 in the wavelength range Az 300 nm. For typical spectral irradiances see Figure A.1. The irradiance at the test specimen surface shall not vary more than ± 10 % in relation to any two points in the specimen holder planeIn order to achieve homogeneous exposure conditions operate the apparatus according to the manufacturer's instructions (e. g. replacement of lamps and repositioning of specimens) and use dummy specimens at void positions.

Test Chamber

The design of the test chamber may vary but it shall be constructed from inert material and provide for uniform irradiance in accordance to 5.1 with means for controlling the black standard temperature (BST) and relative humidity in the dry period.

Specimen arrangement

The test specimen racks shall allow the specimens to:

lie flat in the plane 5 above the horizontal;

be mounted so that the exposed face is in the plane of uniform irradiance.

The specimens shall be attached to stainless steel platens of at least the same size as the specimens by appropriate means. The attachment shall leave an area open to free irradiation so that subsequent tests can be performed or irradiated parts of the specimen.

For inclinations near to horizontal the specimens may be alternatively placed in stainless steel pans of at least the same size as the specimens. The specimens shall be weighted in this arrangement by means of a U shaped stainless frame. The external dimensions of the frame shall correspond to the specimen size.

The cross section of the steel frame shall be (5 ±0,5) mm by approximately 10 mm. The dimension of (5 ± 0.5) mm stands for the width of the cross section, i. e. the plane that is in contact with the specimen. If the specimens are placed in pans, the lower end of the pans shall have sufficient slits or holes to avoid any collection of water. The attachment arrangement shall not restrain the test specimens from changes in dimensions during exposure.

Water supply and spray mechanism

Demineralized water with a maximum conductivity of 500 uS/m shall be used for spraying. In general the temperature of the water to be used in the spraying procedure shall be (25 ± 5) C at the beginning of the spray cycle. Spray nozzles shall provide a uniform and continuous wetting of the exposed specimens sides for defined periods of time.

The flow rate through the nozzles shall be (10 ± 3) litres per min and m2 of the exposed specimen surface.

Cycle timer

A continuously operating cycle timer or controller shall allow programming of the spray cycles. An hour meter shall be provided to record total time of operation and UV exposure5.6

Thermometer

Thermometer capable of measuring the black standard temperature in accordance with EN ISO 4892-1, with means to record the temperature during each cycle.

Radiometer

A radiometer to determine the UV radiant exposure in J/m2 in the wavelength region from 300 nm to 400 nm.

Procedure

General

The test specimens and the black standard thermometer shall be mounted in the specimen holders with their exposed sides facing the lamps (5.1).

Exposure cycle

An exposure cycle has a duration of 360 min and consists of a 300 min dry period followed by a 60 min spray (wet) period in accordance with EN ISO 4892-3. Irradiation is not maintained during the wet period.

Black standard temperature

The black standard temperature (BST) shall be at (60 ± 3) C during the dry period. The air temperature in the test chamber (5.2) shall be controlled to a constant value such that the black standard temperature (BST) equals the required value after 30 min in the dry period.

Chamber heating

During the spray period the chamber heating is turned off.

Relative humidity

The relative humidity during the dry period shall be (10 ± 5) % after 30 min of the dry period.

Procedure

Operate continuously, repeating the programmed cycle, except for servicing the instrument and inspection of test specimens.

If you are still interested in any kind of environmental test chambers, and I'm pleased provide some of our details and project to you. That's more, at present we have more attractive price for you. Welcome for inquiry any time, I will reply asap!

If you want to know more information about climate chambers or our company, please feel free to contact sales@lenpure.com or visit http://www.lenpure.com/ .