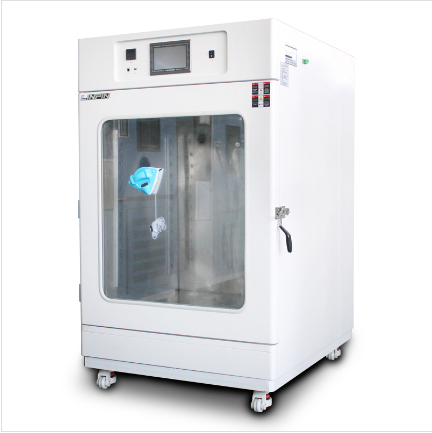

Climate Chambers for ASTM D2247 Water Condensation Tester

Lenpure Programmable Water Condensation Test Chamber give the maximum durability and performance for your most demanding test requirements.It is the necessary test equipment for aviation, Aerospace, automotive, electronics, military and solar panel industry etc.It can be used to test and determine the parameters and performance of electrical, electronic products and materials in the most extreme temperature and humidity conditions.

Feature

●Programmable Touch Screen Controller

●Custom Sizes Available

●Running Time Meter

●Wide Temperature and Humidity Ranges

●Capable of Handling Extreme Temperature and Humidity

●High Performance Even Under Load

●Incandescent Interior Lighting

●Modular,Robust Reliable Construction

●Stainless Steel Interior

●Painted Galvanized Steel Exterior For Long Life

●Heavy-duty Flooring to Support Vehicles

●Mechanical Cooling

●Comprehensive Safety Features

●Refrigeration Gauges

●Refrigeration Sound Deadening Package

●Low or Zero Ozone Depletion Refrigerants

●All Circuits Fused or Circuit Breaker Protected.

●All Wiring Numbered or Color Coded

●Compressor Overload Protection

●Prefabricated for On-Site Installation

Test Standards

This test equipment conforms to following test standards (but not limited to):

●DIN EN ISO 6270-2

●DIN50018

●ASTM D4227

Now let me introduce the standard ASTM D4227 for you.

This practice covers the basic principles and operating procedures for testing water resistance of coatings by exposing coated specimens in an atmosphere maintained at 100% relative humidity so that condensation forms on the test specimens.

This practice is limited to the methods of obtaining, measuring, and controlling the conditions and procedures of tests conducted in 100 % relative humidity. It does not specify specimen preparation, specific test conditions. or evaluation of results.

The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Coated specimens are placed in an enclosed chamber containing a heated, saturated mixture of air and water vapor.The temperature of the chamber is usually maintained at 38℃℃ 1009F). At 100 % relative humidity (RH), a very small temperature difference between the specimen and the surrounding vapor causes the formation of condensation on the specimens. The exposure condition is varied by selecting the duration of the test. Water permeates the coating at rates that are dependent upon the characteristics of the coating. Any effects such as color change, blistering, loss of adhesion, softening, or embrittlement are observed and reported.

Apparatus

Test Chamber, constructed of corrosion-resistant mate rials with supports for the test specimens.

Heated Water Tank, within the test chamber, a water supply, and a water level control

Thermostatic Control, for the water heater with the sensor located adjacent to the specimen holders.

Thermometer, with sensor located adjacent to the specimen holders.

Diagrams and details of the apparatus are shown in the Annex.

Test Specimens

This practice does not cover the preparation of test specimens. The substrate composition and surface preparation, specimen preparation, and the number of specimens should be agreed upon prior to testing.

It's recommended that a control specimen of a paint with known durability be included with each test. Such control specimens can provide warning of changes in test severity in a given apparatus, and can indicate variations in test severity between different apparatuses

It's recommended that at least two replicate specimens of each different coating be used, so as to compensate for variations between specimens and variations in test conditions with the apparatus.

Procedure

Fill the water tank with reagent water conforming to Type IV of Specification D 1193. Tap water should not be used.

Adjust the temperature of the saturated air and water vapor mixture to 38± 29℃ (100 ± 49F).

Support the specimens approximately 15 from the vertical. Slotted wood supports are suitable for flat specimens.Provide for formation of condensation on the specimens by spacing them at least 30 mm apart. Space the specimens so they do not touch each other, any metallic material, or any material capable of acting as a wick. Arrange specimens so that condensate from one specimen cannot drip on other specimens.

Droplets of condensation should appear evenly on the specimen at all times if the chamber is operating properly. The chamber should be mapped throughout the exposure zone to avoid areas where condensation does not occur on the panels and reduce variability in the test. Operate the test continuously with the test chamber closed unless otherwise specified. Short interruptions to inspect or remove specimens are permitted, but such interruptions should occur no more than once each day.

To control for variability within the apparatus, reposition the specimens on a regular basis so that all specimens spend equivalent amounts of time in the various areas of the apparatus (front, back, left, right, and center).

Conclude the test after a specified period of time or after effects from exposure to water are observed.

Wipe the test specimens dry. Rate specimens for changes in color, blistering, etc. Evaluate specimens no less than 5 min and no more than 10 min after removal from test as the effects from water exposure can change within a short time. Remove only as many specimens as can be rated within the specified time.

If possible, rate the specimens again after they have been removed from the test for a recovery period long enough that moisture absorbed within the specimens dries out and the specimens reach moisture equilibrium with room air. A recovery period from 12 to 24 h is generally sufficient.

The post-recovery rating allows evaluation of the permanent effects of the exposure as distinct from the transient effects, and is especially important for evaluation of color and gloss.

If you are still interested in any kind of environmental test chambers, and I'm pleased provide some of our details and project to you. That's more, at present we have more attractive price for you. Welcome for inquiry any time, I will reply asap!

If you want to know more information about climate chambers or our company, please feel free to contact sales@lenpure.com or visit http://www.lenpure.com/ .

●Programmable Touch Screen Controller

●Custom Sizes Available

●Running Time Meter

●Wide Temperature and Humidity Ranges

●Capable of Handling Extreme Temperature and Humidity

●High Performance Even Under Load

●Incandescent Interior Lighting

●Modular,Robust Reliable Construction

●Stainless Steel Interior

●Painted Galvanized Steel Exterior For Long Life

●Heavy-duty Flooring to Support Vehicles

●Mechanical Cooling

●Comprehensive Safety Features

●Refrigeration Gauges

●Refrigeration Sound Deadening Package

●Low or Zero Ozone Depletion Refrigerants

●All Circuits Fused or Circuit Breaker Protected.

●All Wiring Numbered or Color Coded

●Compressor Overload Protection

●Prefabricated for On-Site Installation

Test Standards

This test equipment conforms to following test standards (but not limited to):

●DIN EN ISO 6270-2

●DIN50018

●ASTM D4227

Now let me introduce the standard ASTM D4227 for you.

This practice covers the basic principles and operating procedures for testing water resistance of coatings by exposing coated specimens in an atmosphere maintained at 100% relative humidity so that condensation forms on the test specimens.

This practice is limited to the methods of obtaining, measuring, and controlling the conditions and procedures of tests conducted in 100 % relative humidity. It does not specify specimen preparation, specific test conditions. or evaluation of results.

The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Coated specimens are placed in an enclosed chamber containing a heated, saturated mixture of air and water vapor.The temperature of the chamber is usually maintained at 38℃℃ 1009F). At 100 % relative humidity (RH), a very small temperature difference between the specimen and the surrounding vapor causes the formation of condensation on the specimens. The exposure condition is varied by selecting the duration of the test. Water permeates the coating at rates that are dependent upon the characteristics of the coating. Any effects such as color change, blistering, loss of adhesion, softening, or embrittlement are observed and reported.

Apparatus

Test Chamber, constructed of corrosion-resistant mate rials with supports for the test specimens.

Heated Water Tank, within the test chamber, a water supply, and a water level control

Thermostatic Control, for the water heater with the sensor located adjacent to the specimen holders.

Thermometer, with sensor located adjacent to the specimen holders.

Diagrams and details of the apparatus are shown in the Annex.

Test Specimens

This practice does not cover the preparation of test specimens. The substrate composition and surface preparation, specimen preparation, and the number of specimens should be agreed upon prior to testing.

It's recommended that a control specimen of a paint with known durability be included with each test. Such control specimens can provide warning of changes in test severity in a given apparatus, and can indicate variations in test severity between different apparatuses

It's recommended that at least two replicate specimens of each different coating be used, so as to compensate for variations between specimens and variations in test conditions with the apparatus.

Procedure

Fill the water tank with reagent water conforming to Type IV of Specification D 1193. Tap water should not be used.

Adjust the temperature of the saturated air and water vapor mixture to 38± 29℃ (100 ± 49F).

Support the specimens approximately 15 from the vertical. Slotted wood supports are suitable for flat specimens.Provide for formation of condensation on the specimens by spacing them at least 30 mm apart. Space the specimens so they do not touch each other, any metallic material, or any material capable of acting as a wick. Arrange specimens so that condensate from one specimen cannot drip on other specimens.

Droplets of condensation should appear evenly on the specimen at all times if the chamber is operating properly. The chamber should be mapped throughout the exposure zone to avoid areas where condensation does not occur on the panels and reduce variability in the test. Operate the test continuously with the test chamber closed unless otherwise specified. Short interruptions to inspect or remove specimens are permitted, but such interruptions should occur no more than once each day.

To control for variability within the apparatus, reposition the specimens on a regular basis so that all specimens spend equivalent amounts of time in the various areas of the apparatus (front, back, left, right, and center).

Conclude the test after a specified period of time or after effects from exposure to water are observed.

Wipe the test specimens dry. Rate specimens for changes in color, blistering, etc. Evaluate specimens no less than 5 min and no more than 10 min after removal from test as the effects from water exposure can change within a short time. Remove only as many specimens as can be rated within the specified time.

If possible, rate the specimens again after they have been removed from the test for a recovery period long enough that moisture absorbed within the specimens dries out and the specimens reach moisture equilibrium with room air. A recovery period from 12 to 24 h is generally sufficient.

The post-recovery rating allows evaluation of the permanent effects of the exposure as distinct from the transient effects, and is especially important for evaluation of color and gloss.

If you are still interested in any kind of environmental test chambers, and I'm pleased provide some of our details and project to you. That's more, at present we have more attractive price for you. Welcome for inquiry any time, I will reply asap!

If you want to know more information about climate chambers or our company, please feel free to contact sales@lenpure.com or visit http://www.lenpure.com/ .